Abstract

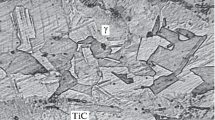

Rapid solidification by electron beam surface melting of a Mo-base high-speed steel (M7) has produced microstructural features different from those observed in the conventionally processed material. As a result of rapid solidification, the volume percent of the carbide phases formed has decreased sharply and has resulted in the formation of M2C and M23C6 carbide phases, while in the conventionally processed material, M6C and MC carbides were present. Microanalysis of the extracted carbides formed by electron beam melting has yielded an intriguing finding. M23C6 is found to be unusually rich in molybdenum, tungsten, and vanadium; the concentration of (Mo + W), for instance, is approximately 60 wt pct. The corresponding values for Fe and Cr are surprisingly low (6 wt pct Cr and 1 wt pct Fe). This is in marked contrast with carbides encountered in the conventionally processed high-speed steel, where Cr and Fe are the major constituents. The shift in composition of the carbide phases could be attributed to the accelerated evaporation of chromium during surface melting as compared to the evaporation of Mo, W, and V.

Similar content being viewed by others

References

E.J. Galda and R.W. Kraft:Metall. Trans., 1974, vol. 5, pp. 1727–33.

H. Brandis, E. Haberling, and H.H. Weigand:Thyssen Edelst. Techn. Ber., 1981, vol. 7 (2), pp. 1–18.

W.B. Pearson:Handbook of Lattice Spacing and Structures of Metals, Pergamon Press, Oxford, United Kingdom, 1967.

E. Staska, R. Bloch, and A. Kulmburg:Microchim. Acta, Wien, 1974, suppl. 5, pp. 111–27.

Y.-W. Kim, P.R. Strutt, and H. Nowotny:Metall. Trans. A, 1979, vol. 10A, pp. 881–86.

I.R. Sare and R.W. Honeycombe:J. Mater. Sci., 1978, vol. 13, pp. 1991–2002.

J.J. Rayment and B. Cantor:J. Mater. Sci., 1978, vol. 12, pp. 156–63.

A. Tauqir, H. Nowotny, and P.R. Strutt:Rapidly Solidified Alloys and Their Mechanical & Magnetic Properties, MRS Proc., Boston, MA, 1985, vol. 56, pp. 425–28.

A. Tauqir, P.G. Klemens, and P.R. Strutt:J. Appl. Phys., 1987, vol. 62, pp. 3953–59.

J.J. McCarthy:Metallurgical Thin Film Correction Module, NS-885-E, Tracor Northern, Inc., Middleton, WI, 1981.

J.C. Schuster: University of Vienna, Vienna, Austria, unpublished research, 1986.

P.G. Klemens:J. Appl. Phys., 1976, vol. 47 (5), pp. 2165–74.

D.A. Schauer, W.H. Giedt, and S.M. Shintakn:Welding J., 1978, pp. 127s–133s.

B.H. Kear, J.W. Mayer, J.M. Poate, and P.R. Strutt: inMetallurgical Treatises, J. Tien and J. Elliott, eds., AIME, New York, NY, 1982, pp. 321–43.

A. Tauqir, P.R. Strutt, and P.G. Klemens:Mater. Sci. Eng., 1987, vol. 94, pp. 251–58.

Author information

Authors and Affiliations

Additional information

formerly Research Associate, University of Connecticut

Rights and permissions

About this article

Cite this article

Tauqir, A., Nowotny, H. & Strutt, P.R. Studies of Carbides in a Rapidly Solidified High-Speed Steel. Metall Trans A 21, 3021–3026 (1990). https://doi.org/10.1007/BF02647222

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF02647222