Abstract

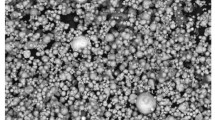

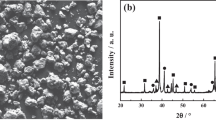

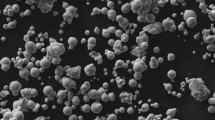

The mechanical properties of carbonyl iron powder shaped by injection molding techniques are affected by the grain size, sintered density, and carbon content. Control of the carbon level depends on several factors, including the binder composition, debinding approach, and sintering conditions (atmosphere, temperature, time, and furnace design). Sintered compacts were densified by containerless hot isostatic pressing, giving smaller grain sizes and superior properties than were possible by pressureless sintering at a high temperature. A quick hot isostatic pressing route (gas forging) with a peak pressure higher than 500 MPa for 1 minute helps retain carbon and results in excellent properties due to a high final density and small grain size. This approach resulted in a final strength of 732 MPa with extensive ductility (23 pct reduction of area) for injection-molded carbonyl iron.

Similar content being viewed by others

References

R. M. German:Powder Injection Molding, Metal Powder Industries Federation, Princeton, NJ, 1990, pp. 1–22, pp. 457–58.

J. E. Japka:J. Met., 1988, vol. 40 (8), pp. 18–21.

F. L. Ebenhoech:Prog. Powder Metall., 1986, vol. 42, pp. 133–40.

R. M. German:Adv. Powder Metall., 1989, vol. 3, pp. 51–66.

G. Cizeron:Compt. Rend., 1958, vol. 244, pp. 3060–63.

G. Cizeron:Compt. Rend., 1957, vol. 245, pp. 2051–54.

F. V. Lenel, G. S. Ansell, and J. R. Strife:Modern Developments in Powder Metallurgy, H. H. Hausner and W. E. Smith, eds., Metal Powder Industries Federation, Princeton, NJ, 1974, vol. 6, pp. 275–92.

H. Fischmeister:Iron Powder Metallurgy, H. H. Hausner, K. H. Roll, and P. K. Johnson, eds., Plenum Press, New York, NY, 1968, pp. 262–83.

E. Aigeltinger and J. P. Drolet:Modern Developments in Powder Metallurgy, H. H. Hausner and W. E. Smith, eds., Metal Powder Industries Federation, Princeton, NJ, 1974, vol. 6, pp. 323–41.

K. Nii:Z. Metallkd., 1970, vol. 61, pp. 935–41.

R. Watanabe and Y. Masuda:Trans. Jpn. Inst. Met., 1972, vol. 13, pp. 134–39.

M. Oxley and G. Cizeron:Int. J. Powder Metall., 1965, vol. 1 (2), pp. 15–27.

J. J. Bacmann and G. Cizeron:Int. J. Powder Met., 1969, vol. 5 (2), pp. 39–53.

C. W. Corti and P. Cotterill:Powder Metall. Int., 1974, vol. 6, pp. 23–25.

B. N. Singh and D. H. Houseman:Powder Metall. Int., 1971, vol. 3, pp. 26–29.

D. Uskokovic, D. Delic, and M. M. Ristic:Int. J. Powder Metall. Powder Technol., 1975, vol. 11, pp. 189–93.

H. Hickling and D. S. Coleman:Powder Metall., 1982, vol. 25, pp. 25–34.

K. F. Hens, S. T. Lin, R. M. German, and D. Lee:JOM, 1989, vol. 41 (8), pp. 17–21.

B. K. Lograsso, A. Bose, B. J. Carpenter, C. I. Chung, K.F. Hens, D. Lee, S. T. Lin, C. X. Liu, R. M. German, R. M. Messler, P. F. Murley, B. O. Rhee, C.M. Sierra, and J. Warren:Int. J. Powder Metall., 1989, vol. 25, pp. 337–48.

D. S. Madan: Ph. D. Thesis, Rensselaer Polytechnic Institute, Troy, NY, 1988.

A. R. Poster and H. H. Hausner:Modern Developments in Powder Metallurgy, H. H. Hausner, ed., Plenum Press, New York, NY, 1966, vol. 2, pp. 26–43.

T. T. Lam: Report No. LBL-8001, Lawrence Berkeley Laboratory, University of California, Berkeley, CA, June 1978.

S. T. Lin and R. M. German:Powder Metall. Int., 1989, vol. 21 (5), pp. 19–24.

L. C. Browning, T. W. Dewitt, and P. H. Emmett:J. Am. Chem. Soc, 1950, vol. 72, pp. 4211–17.

O. Kubaschewski and J. A. Catterall:Thermochemical Data of Alloys, Pergamon Press, London, 1956, pp. 64–68.

L. S. Darkin and R. W. Gurry:Physical Chemistry of Metals, McGraw-Hill, New York, NY, 1953, pp. 212–22.

R. M. Conaway:Adv. Mater. Processes, 1989, June, vol. 137, pp. 35–39.

R. E. Wiech, Jr.: U. S. Patent No. 4,661,315, April 28, 1987.

P. Bhave, W. Dormon, and D. Teel:Modern Developments in Powder Metallurgy, P.U. Gummeson and D. A. Gustafson, eds., Metal Powder Industries Federation, Princeton, NJ, 1988, vol. 18, pp. 333–49.

D. R. Gaskell:Introduction to Metallurgical Thermodynamics, 2nd ed., McGraw-Hill, New York, NY, 1981, pp. 272–316.

E. A. Brandes:Smithells Metals Reference Book, 6th ed., Butterworth’s, London, 1983, pp. 22–128.

R. Haynes:The Mechanical Behaviour of Sintered Metal, Freund Publishing House, London, 1981.

A. Salak, V. Miskovic, E. Dudrova, and E. Rudnayova:Powder Metall. Int., 1974, vol. 6, pp. 128–32.

R. Haynes:Powder Metall., 1977, vol. 20, pp. 17–20.

M. D. Hamiuddin:Powder Metall. Int., 1986, vol. 18, pp. 73–76.

J. A. Lund:Can. Metall. Q., 1984, vol. 23, pp. 131–37.

S. L. Forss:Modern Developments in Powder Metallurgy, H. H. Hausner, ed., Plenum Press, New York, NY, 1966, vol. 2, pp. 3–11.

R. L. Coble:Powder Metall. Int., 1978, vol. 10 (3), pp. 128–30.

E. Arzt, M. F. Ashby, and K. E. Easterling:Metall. Trans. A, 1983, vol. 14A, pp. 211–21.

M. R. Ashby:Hot Isostatic Pressing Diagrams HIP 487, Update May 1988, Engineering Department, Cambridge University, Cambridge, Sept. 1987.

K. Isonishi and M. Tokizane.Int. J. Powder Metall., 1989, vol. 25, pp. 187–94.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Lin, S.T., German, R.M. Mechanical properties of fully densified injection-molded carbonyl iron powder. Metall Trans A 21, 2531–2538 (1990). https://doi.org/10.1007/BF02646998

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF02646998