Abstract

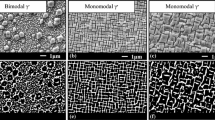

The use of the solid- to- liquid phase transformation of LiF to store thermal energy is under consideration for a space- based solar dynamic system. Although advantageous in terms of its energy density, the melting point of this salt (1121K) is beyond the commonly accepted upper- use temperature of 1100 K for chromium- bearing superalloys in vacuum. However, one commercially available nickel- base superalloy (Hastelloy B- 2) is chromium free; unfortunately, because of its high molybdenum content, this alloy can form phases that cause high- temperature embrittlement. To test the suitability of Hastelloy B- 2, it has been exposed to molten LiF, its vapor and vacuum at 1173 K for 2500, 5000, and 10 h. For control, the chromium- containing cobalt- base Haynes alloy 188 and nickel- base Haynes alloy 230 were also exposed to LiF and vacuum at 1173 K for 5000 h. Neither LiF nor vacuum exposures had any significant effect on Hastelloy B- 2 in terms of microstructural surface damage or weight change. Measurement of the post exposure tensile properties of Hastelloy B- 2, nevertheless, revealed low tensile ductility at 1050 K. Such embrittlement and low strength at elevated temperatures appear to preclude the use of Hastelloy B- 2 as a containment material for LiF. Little evidence of significant attack by LiF was seen in either of the chromium- containing superalloys; however, considerable weight loss and near- surface microstructural damage occurred in both alloys exposed to vacuum. Although measurement of the post exposure room-temperature tensile properties of Haynes alloys 188 and 230 revealed no significant loss of strength or ductility, the severe degree of microstructural damage found in unshielded alloys exposed to vacuum indicates that chromium-bearing superalloys might also be unsuitable for prolonged containment of LiF in space above 1100 K. Keywords

Similar content being viewed by others

References

T.L. Labus, R.R. Secunde, and R.G. Lovely, “Solar Dynamic Power for Space Station Freedom,” NASATM-102016, National Aeronautics and Space Administration, 1989

A.K. Misra and J.D. Whittenberger, Fluoride Salts and Container Materials for Thermal Energy Storage Applications in the Tem- perature Range 973-1400 K,Energy—New Frontiers (IECEC ’ 87), American Institute of Astronautics and Aeronautics, 1987, p 188–201

J.D. Whittenberger and A.K. Misra,J. Mater. Eng., Vol 9,1987, p 293–302

H.J. Strumpf and M.G. Coombs, Solar Receiver for the Space Station Brayton Engine,Proc. Gas Turbine Conference and Exhibition, ASME Paper 87-GT-252, American Society of Mechanical Engineers, 1987

R.C. Schulze, “The Corrosion of Superalloys by Lithium Fluoride in a Cyclic High Temperature Corrosion Environment,” NASA CR-54781, National Aeronautics and Space Administration, 1965

J.N. Mattavi, F.E. Heffner, and A.A. Miklos, “The Sterling Engine for Underwater Vehicle Applications,” Paper 690731, Society of Automotive Engineers, 1969, p 2376–2400

E.R. Cprek, “Metallurgical Studies of High Temperature Alloy Capsules after Long Time Cyclic Corrosion Tests as Containers for Lithium Fluoride,” GM Research Laboratories Report GMR- 2690, Part 7.109, General Motors, 1978

G.A.A. Asselman,Energy Conv., Vol 16, 1976, p 35–47

J.D. Whittenberger,J. Mater. Eng., Vol 12, 1990, p 211–226

J.D. Whittenberger,J. Mater. Eng. Perform., Vol 1, 1992, p 469- 482

J.D. Whittenberger,J. Mater. Eng. Perform., Vol 3, 1994, p 754- 762

J.D. Whittenberger,T J. Mater. Eng. Perform., Vol 3, 1994, p 763–774

J.D. Whittenberger,J. Mater. Eng. Perform., Vol 2, 1993, p 745- 757

J.D. Whittenberger,J. Mater. Eng. Perform., Vol 3, 1994, p 91- 103

D.T. Bourgette, “Evaporation of Iron-, Nickel- and Cobalt-base Alloys at 760 to 980 °C in High Vacuums,” ORNL-3677, Oak Ridge National Laboratory, 1964

D.T. Bourgette and H.E. McCoy, Trans. ASM, Vol 59, 1966, p 324–339

D.T. Bourgette, “Vaporization Phenomena of Haynes Alloy No. 25 to 1150 °C,” ORNL-TM-1786, Oak Ridge National Laboratory, 1967

D.T. Bourgette, “Evaporation of Hastelloy N and Haynes Developmental Alloy No. 188,” in ORNL-4250, Oak Ridge National Laboratory, 1970, p 204–209

Haynes International Data Sheets for Hastelloy B-2 and personal communication with M. F. Rothman, Haynes International

J.D. Whittenberger,J. Mater. Eng., Vol 10, 1988, p 247–258

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Whittenberger, J. Tensile Properties and Structure of Several Superalloys after Long- Term Exposure to LiF and Vacuum at 1173 K. JMEP 4, 657–673 (1995). https://doi.org/10.1007/BF02646442

Issue Date:

DOI: https://doi.org/10.1007/BF02646442