Abstract

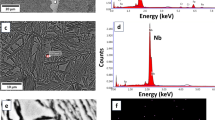

Carbon (0.07%) steel samples containing about 0.04% Nb singly and in combination with nitrogen were carburized in a natural Titas gas atmosphere at a temperature of 1223 K (950 °C) and a pressure of about 0.10 MPa for 1/2 to 4 h, followed by slow cooling in the furnace. Their microstructures were studied by optical microscopy. The austenite grain size of the case and the case depths were determined on baseline samples of low-carbon steels and also on niobium and (Nb + N) microalloyed steel samples. It was found that, when compared to the baseline steel, niobium alone or in combination with nitrogen decreased the thickness of cementite network near the surface of the carburized case of the steels. However, niobium in combination with nitrogen was more effective than niobium in reducing the thickness of cementite network. Niobium with or without nitrogen inhibited the formation of Widmanstätten cementite plates at grain boundaries and within the grains near the surface in the hypereutectoid zone of the case.

It was also revealed that, when compared to the baseline steel, niobium decreased the case depth of the carburized steels, but that niobium with nitrogen is more effective than niobium alone in reducing the case depth. Niobium as niobium carbide (NbC) and niobium in the presence of nitrogen as niobium carbonitride, [Nb(C,N)] particles refined the austenite grain size of the carburized case, but Nb(C,N) was more effective than NbC in inhibiting austenite grain growth.

Similar content being viewed by others

References

S. Preston,Mater. Sci. Technol., Vol 9, July 1993, p 615–619

V.I. Slavov, V.N. Zadorozhnaya, and A.I. Slavova,Russ. Metall., Vol 3,1992, p 83–88

B.M. Khusid,Wear, Vol 165,1993, p 109–112

S. Preston,J. Heat Treat., Vol 8 (No. 2), 1990, p 93–99

M.N. Haque, M.Sc. engineering thesis, Bangladesh University of Engineering and Technology, Dhaka, 1988

M.N. Haque and M.M.A. Bepari,J. Inst. Eng., (Bangladesh), Vol 17 (No. 1), Jan 1989, p 37–47

N. Geru and T. Vasile,Metallurgica (Bucharest), Vol 10, 1994, p 10–11

M.M.A. Bepari and M. Ibrahim,J. Inst. Eng. (Bangladesh), Vol 11 (No. 2), April 1983, p 23–35

“Natural Resources and Industrial Prospects in Bangladesh,” Seminar, Department of Chemical Engineering, Bangladesh University of Engineering and Technology, Dhaka, 1972, p B-2

M.A. Islam, M.Sc. engineering thesis, Bangladesh University of Engineering and Technology, Dhaka, 1994

C.A. Stickels, inASM Handbook, Vol 4, ASM International, 1991, p 312–324

M.M.A. Bepari, M.Met. thesis, University of Sheffield, U.K., 1978

J.H. Woodhead, “Vanadium in High Strength Steel,” in seminar proceedings (Chicago), 1979, p 3

M.Z. Haque, M.Sc. engineering thesis, Bangladesh University of Engineering and Technology, Dhaka, 1989

P.R. Rios and R.W.K. Honeycomb,Mater. Sci. Technol., Vol 8, 1992,p 1057–1062

M.M.A. Bepari, and J.A. Whiteman,J. of Mat. Proc. Tech., Vol. PRO 056/1-4,1996, p 834–846

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Islam, M., Bepari, M.M.A. Effects of niobium additions on the structure, depth, and austenite grain size of the case of carburized 0.07% C steels. JMEP 5, 593–597 (1996). https://doi.org/10.1007/BF02646087

Issue Date:

DOI: https://doi.org/10.1007/BF02646087