Abstract

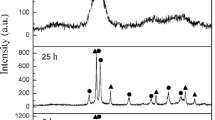

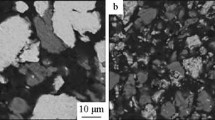

The elemental powder metallurgy (EPM) process is used to prepare TiAl-base intermetallics. An EPM process conducted by two-stage solid-state hot pressing was employed to prepare TiAl-base intermetallics and to investigate the resulting microstructural changes. The results showed that the TiAl3 phase forms in the first stage. During the temperature increase to the second sintering stage, lamellar phases start to precipitate in the TiAl3 matrix. Further, the TiAl3 phase transforms to TiAl, and Ti3Al layers develop in the remaining titanium particles. Meanwhile, the lamellar phases grow into ring-type structures between the TiAl matrix and the Ti3 Al layers. After the second stage, the remaining titanium particles are fully reacted, and a microstructure of Ti3Al phases enclosed by fine-grained lamellar rings in the TiAl matrix is developed.

Similar content being viewed by others

References

G.-X. Wang and M. Dahms, An Overview: TiAl-Based Alloys Prepared by Elemental Powder Metallurgy,Powder Metall. Int., Vol 24 (No. 4), 1992, p 219–225

G.-X. Wang and M. Dahms, Synthesizing Gamma-TiAl Alloys by Reactive Powder Process,J. Met., Vol 45 (No. 5), 1993, p 52–56

K. Shibue, Suppression of Pores for TiAl Intermetallic Compound Prepared by Reactive Sintering,Sumitomo Light Met. Tech. Rep., Vol 32 (No. 2), 1991, p 95–101

P.L. Sullivan, HIP Processing of Ti-Al Intermetallic Using Blended Elemental Powder,J. Mater. Process. Technol, Vol 38, 1993, p 1–13

G.-X. Wang and M. Dahms, An Effective Method for Reducing Porosity in the Titanium Aluminide Alloy Ti52AI48 Prepared by Elemental Powder Metallurgy,Scr. Metall. Mater., Vol 26 (No.9), 1992, p 1469–1474

M. Dahms, F. Schmelzer, J. Seeger, and B. Wildhagen, Microstructure and Mechanical Properties of γ Base Titanium Alu- minide Produced from Extruded Elemental Powders,Mater. Sci. Technol., Vol 8 (No. 4), 1992, p 359–362

J.C. Rawers and W. Wrzesinski, Heat Treatment of Reaction-Sintered Hot-Pressed TiAl,Scr. Metall. Mater., Vol 24 (No. 10), 1990, p 1985–1990

G.-X. Wang and M. Dahms, Influence of Heat Treatment on Microstructure of Ti-35wt.%Al Prepared by Elemental Powder Metallurgy,Scr. Metall. Mater., Vol 26 (No. 5), 1992, p 717- 722

F.J.J. van Loo and G.D. Rieck, Diffusion in the Titanium-Aluminium System, Part I: Interdiffusion between Solid Al and Ti or Ti-Al Alloys,Acta Metall., Vol 21 (No. 1), 1973, p 61–71

F.J.J. van Loo and G.D. Rieck, Diffusion in the Titanium-Aluminium System, Part II: Interdiffusion in the Composition Range between 25 and 100 at% Ti,Acta Metall., Vol 21 (No. 1), 1973,p 73–84

J.C. Rawers, W. Wrzesinski, E.K. Roub, and R.R. Broun, TiAl-SiC Composites Prepared by High Temperature Synthesis,Mater. Sci. Technol., Vol 6 (No. 2), 1990, p 187–191

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Yang, J., Teoh, K. & Hwang, W. Solid-state hot pressing of elemental aluminum and titanium powders to form TiAl (γ + α2) intermetallic microstructure. JMEP 5, 583–588 (1996). https://doi.org/10.1007/BF02646085

Issue Date:

DOI: https://doi.org/10.1007/BF02646085