Abstract

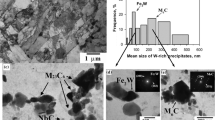

A carburized coarse-grained AISI 8620 steel was subjected to three postcarburization heat treatments: a) direct oil quench from the carburizing temperature (1700°F), b) direct oil quench, reheat to 1550°F and oil quench, and c) slow cool, reheat to 1550°F and oil quench, reheat to 1450°F and oil quench. The latter two treatments refined the austenitic grain size over that resulting from the direct quench and caused a reduction in the size of the marten-site plates and of the number and/or size of the microcracks within the plates. The refine-ment of the microstructure and the reduction of the number of microcracks resulted in greatly improved fatigue resistance,i.e., from fatigue limits of 140 to 250 ksi maximum cyclic stress for the direct quench and double reheat conditions, respectively. Subcritical crack growth was transgranular, but the mode of unstable crack propagation was mixed transgranular and intergranular in the direct quench and single reheat specimens. Obser -vations of microcrack coalescence and fracture surface features suggest that microcracks are instrumental in the transgranular mode of failure.

Similar content being viewed by others

References

A. R. Marder and A. O. Benscoter:Trans. ASM, 1968, vol. 61, pp. 293–99.

A. R. Marder, A. 0. Benscoter, and G. Krauss:Met. Trans., 1970 vol 1 pp 1545–49.

M. G. Mendiratta and G. Krauss:Met. Trans., 1972, vol. 3, pp. 1755–60.

R. G. Davies and C. L. Magee:Met. Trans., 1972, vol. 3, pp. 307–13.

M. G. Mendiratta, J. Sasser, and G. Krauss:Met. Trans., 1972, vol. 3, pp. 351–53.

R. A. Grange:Trans. ASM, 1969, vol. 62, pp. 1024–27.

A. W. Rauch and W. R. Thurtle:Metals Progr., April 1956, vol. 69, pp. 73–76.

J. G. Roberts and R. L. Mattson:Fatigue Durability of Carburized Steel, p. 102, American Society for Metals, Metals Park, Ohio, 1957.

L. Jena and P. Heich:Met. Trans., 1972, vol. 3, pp. 588–90.

Metals Handbook, 8th ed., vol. 7, p. 60, American Society for Metals, Metals Park, Ohio, 1972.

Modem Steels and Their Properties, 6th ed., p. 106, Bethlehem Steel Corp., Bethlehem, Pa., 1967.

Metals Handbook, 5th ed., p. 684, American Society for Metals Metals Park Ohio, 1948.

R. L. Miller:Trans. ASM, 1964, vol. 57, pp. 893–99.

Author information

Authors and Affiliations

Additional information

C. A. Apple, formerly Postdoctoral Fellow, Lehigh University, Bethlehem, Pa. 18015

Rights and permissions

About this article

Cite this article

Apple, C.A., Krauss, G. Microcracking and fatigue in a carburized steel. Metall Trans 4, 1195–1200 (1973). https://doi.org/10.1007/BF02644511

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF02644511