Abstract

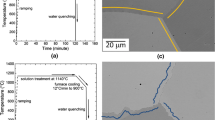

Creep rupture specimens taken from directionally solidified ingots of IN-738 and Nichrome in which the grain boundaries were oriented longitudinally, transversely, and 45 deg to the stress axis have been tested over a range of temperature and stress. For both alloys, the ductility was appreciably higher in the longitudinal orientation; but in IN-738, the creep strength was higher in the other two orientations. The net effect on rupture life was small for the superalloy. The nichrome showed much greater scatter which was due partly to inhomogeneous deformation and local recrystallization at the higher temperatures. Because of the recrystallization, even the longitudinal specimens showed intergranular failure for nichrome. The microstructural features of intergranular cracking both internally and on the surface are documented. It is suggested that surface cracking may be an important contributory factor in leading to reduced life with decreased section size which is commonly observed in conventionally cast superalloys.

Similar content being viewed by others

References

F.L. VerSnyder and M. E. Shank:Mater. Sci. Eng., 1970, vol. 6, pp. 213–47.

G. S. Cole and R. S.Cremisio: Chapter 17,TheSuperalloys,C. T. Sims and W. C. Hagel, eds., John Wiley and Sons, 1972.

G. F. Harrison and G. P. Tilly, International Conference on Creep and Fatigue in Elevated Temperature Applications, Philadelphia, September 1973, Inst. Mech. Eng., paper C222.

D. A. Spera, M. A. H. Howes, and P. T. Bizon: NASA TMS-52975, March 1971.

D. F. Mowbray, D. A. Woodford, and D. E. Brandt:Fatigue at Elevated Tempe- ratures, ASTM STP 520, 1973.

D. A. Woodford and D. F. Mowbray,Mater. Set Eng., 1974, to be published.

G. Oxx, International Conference on Creep and Fatigue in Elevated Tempera- ture Applications, Philadelphia, September 1973,Inst. Mech. Eng., paper C212.

C. Crussard and R. Tamhanker,Trans. TMS-AIME, 1958, vol. 212,pp. 718–25.

B. J. Piearcey, B. H. Kear, and R. W. Smashey:Trans. ASM, 1967, vol 60, pp. 634–45.

P. M. Chaky and C. J. McMahon, Jr.:Met. Trans., 1973, vol. 5, pp. 441–50.

U.R. Widmer and N. J. Grant:J Basic Eng., December 1960, pp. 829–38.

S. M. Copley, B. H. Kear, and G. M. Rowe:Mat. Sci. Eng., 1972, vol. 10, pp. 87–91.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Woodford, D.A., Frawley, J.J. The effect of grain boundary orientation on creep and rupture of IN-738 and nichrome. Metall Trans 5, 2005–2013 (1974). https://doi.org/10.1007/BF02644493

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/BF02644493