Abstract

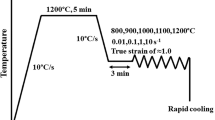

The behavior of a Ni-Cr-Co base alloy with significant additions of Mo, Ti and Al (Nimonic 105) under hot working conditions was studied using hot compression tests in the temperature range of 1223 to 1523 K and strain rates between 0.38 and 64.3 s-1.

The microstructure of the Nimonic 105 is complex and the matrix contains second phases in the form of Ni3 (Ti, Al) dispersion (γ′), various Cr and Ti carbides and titanium cyanonitrides inclusions.

However, the results show that above the dissolution temperature of the γ′ phase, the alloy behaves like a single phase nickel-base solid solution from the point view of steady state flow stress-temperature-strain rate relationships, and the activation energies for hot working and static recrystallization.

Under deformation conditions where the γ′ phase is present, as in the case of creep, the activation energy is almost doubled. The hot working temperature range giving sound product is 1280 to 1450 K (170 K) at a strain rate of 0.4 s-1 and decreases to 1400 to 1480 K (80 K) at a strain rate of 65 s-1. At temperatures above the higher limit the alloy suffers intercrystalline cracks due to hot shortness and at temperatures below the lower limit the alloy suffers transcrystalline cracks due to excessive strain hardening.

Similar content being viewed by others

References

A. Taylor and E. A. Floyd:J. Inst. Metals, 1952-53, vol. 81, p. 451.

W. Betteridge:The Nimonic Alloys, Edward Arnold Ltd., London, 1959.

W. Betteridge and A. W. Franklin:J. Inst. Metals, 1950-57, vol. 85, p. 473.

A. W. Franklin, J. Thexton, and D. R. Wood:Joint Int. Conf. Creep, Inst. of Mech. Eng., 1962, vol. 1, pp. 7–21.

A. Chaudhuri:J. Inst. Metals, 1970, vol. 98, p. 114.

C. H. White:J. Inst. Metals, 1969, vol. 97, p. 215.

S. T. Quaass:J. Inst. Metals, 1968, vol. 96, p. 129.

C. W. Weaver:J. Inst. Metals, 1959-60, vol. 88, p. 462.

J. Heslop:J. Inst. Metals, 1962-63, vol. 91, p. 28.

J. L. Uvira and J. J. Jonas:Trans. TMS-AIME, 1968, vol. 242, p. 1619.

S. K. Samanta:J. Iron Steel Inst., 1968, vol. 122, p. 130.

O. Pawelski, G. Grave, and D. Lohr:J Iron Steel Inst., 1970, vol. 147, p. 155.

C. M. Sellars and W. J. McG. Tegart:Rev. Met., 1966, vol. 63, p. 731.

F. Garofalo:Fundamentals of Creep and Creep Rupture in Metals, Macmillan, New York, 1965.

J. P. Dennison, R. J. Llewellyn, and B. Wilshire:J. Inst. Metals, 1967, vol. 95, p. 115.

K. Monma, H. Suto, and H. Oikawa:J. Japan Inst. Metals, 1964, vol. 24, p. 253.

M. R. Achter and P. Shahinian:Trans. ASM, 1959, vol. 51, p. 244.

G. A. Webster and B. J. Piearcy:Metal Sci. J., 1967, vol. l, p.97.

A. J. Ardell and R. B. Nicholson:Acta Met., 1966, vol. 14, p. 1295.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Farag, M.M., Hamdy, M.M. Behavior of a nickel-base high-temperature alloy under hot-working conditions. Metall Trans A 7, 221–228 (1976). https://doi.org/10.1007/BF02644460

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF02644460