Abstract

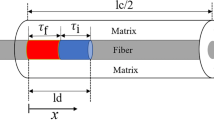

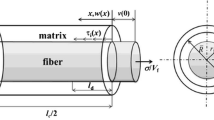

The large-scale plastic deformation behavior of aluminum-stainless steel fiber composites has been examined under conditions of simulated forging. With the load applied perpendicular to the direction of reinforcement, deformation normally occurs in a plane strain mode with no metal flow in the direction of fiber alignment. Two possible types of material damage are identified: (i) void formation in the matrix adjacent to the fibers; (ii) breaking of the fibers, leading to deviations from plane strain. Forming limit criteria for both types of damage are established, which are related to the workpiece geometry and friction parameters of the system through plasticity theory. These criteria form the basis of a rational approach to design of processes for forging complex shapes from fiber-reinforced composite materials having a ductile matrix.

Similar content being viewed by others

References

I. J. Toth, W. D. Brentnall, and D. G. Menke:J. Metals, Oct. 1972, vol 24 p. 37.

M. Salkind, F. George, and W. Tice:Trans. TMS-AIME, 1969, vol. 245, p. 2339.

B. Avitzur: “Deformability of Fiber-Reinforced Material and the Effect of Plastic Deformation on its Mechanical Properties”, Ph. D. Thesis, Lehigh University, Bethlehem, Pa., 1969.

S. Kobayashi:Trans. ASME, 1970, vol. 92, Series B, p. 391.

P. W. Lee and H. A. Kuhn:Met. Trans., 1973, vol. 4, p. 969.

W. A. Backofen:Deformation Processing, p. 163, Addison-Wesley, Reading, Mass., 1972.

G. W. Rowe:An Introduction to the Principles of Metalworking, p. 240, Arnold, London, 1965.

S. Kalpakjian:Mechanical Processing of Materials, p. 131, Van Nostrand, Princeton, N. J., 1967.

A. T. Male and M. G. Cockcroft:J. Inst. Metals, 1964-65, vol. 93, p. 39.

W. A. Backofen: see Ref. 6, p. 40.

J. N. Goodier:Trans. ASME, 1933, vol. 55, p. 39.

M. F. Ashby:Phil. Mag, 1966, vol. 14, p. 1157.

H. R. Vorhees and J. W. Freeman:Report on the Elevated Temperature Properties of Aluminum and Magnesium Alloys, ASTM Publication 291, philadelphia, pa., October. 1961.

M. R. Pinnel and A. Lawley:Met. Trans., 1970, vol. 1, p. 1337.

A. Pattnaik and A. Lawley:Met. Trans., 1974, vol. 5, p. 111.

Author information

Authors and Affiliations

Additional information

T. ERTÜRK, formerly Research Assistant (Academic Program of the Agency for International Development, Department of State), Department of Metallurgical Engineering, Drexel University, Philadelphia, Pa.

Rights and permissions

About this article

Cite this article

Ertürk, T., Kuhn, H.A. & Lawley, A. Forging of metal-matrix composites-forming limit criteria. Metall Trans 5, 2295–2303 (1974). https://doi.org/10.1007/BF02644009

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/BF02644009