Abstract

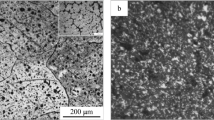

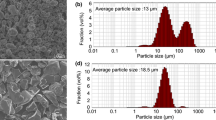

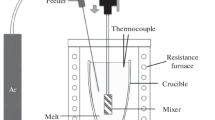

The effect of isothermal exposure and thermal cycling on the toughness of B/Al (1100), B/Al (6061), and A12O3/A1 composites has been investigated. In B/Al (1100), isothermal exposure at 773 K for 45 × 104 s (125 hours) reduced toughness, measured by the work of fracture, from 76 kJm-2 to 10 kJm-2, and a similar reduction occurred after equivalent thermal cycling. The corresponding reduction in toughness after isothermal exposure in B/Al (6061) was from 44.5 kJm-2 to 8 kJm-2; however, the effect of thermal cycling was less detrimental. In the FP-A12O3/A1 composite, the work of fracture was insensitive to both forms of thermal treatment. Changes in the toughness of the B/Al composites have been correlated with and analyzed in terms of modifications to matrix, fiber, and interface properties, in particular, matrix softening, interface reaction products, and fiber notch sensitivity.

Similar content being viewed by others

References

J. F. Haskins and J. R. Kerr: “Time-Temperature-Stress Capabilities of Composite Materials for Supersonic Cruise Aircraft Applications”, 1977, NASA Technical Report #N-77-18035.

M. A. Wright:Metall. Trans. A, 1975, vol. 6A, p. 129.

H.H. Grimes, R. A. Lad, and J. E. Maisel:Metall. Trans. A, 1977, vol. 8A, p. 1999.

M. K. White and M. A. Wright: “Investigations into the Mechanics of Thermal Cycling Damage in Metal Matrix Composites”, University of Tennessee Space Institute, December 1976, ONR Technical Report, Contract #N00014-75-C-0352.

W.H. Kim, M. J. Koczak, and A. Lawley:ICCM/2, Proceedings of the 1978 International Conference on Composite Materials, B. Noton, R. Signorelli, K. Street, and L. Phillips, eds., The Metallurgical Society of AIME, New York, NY, 1978, p. 487.

H.E. Tattersall and G. Tappin:J. Mat. Sci., 1966, vol. 1, p. 296.

J. E. Hack and G.C. Strempek: “Fabrication of Aluminum Oxide Fiber-Reinforced Aluminum Matrix Composites,” NASA Report #CR-165184 (Contract NAS3-21013), Fiber Materials, Inc., Biddeford, ME, November 1980.

G. Thomas:J. Inst. Metals, 1961-62, vol. 90, p. 57.

G. S. Doble, “Fabrication Process Development of Boron/Aluminum Fan Blades for High Bypass Engines,” NASA #CR-165252, TRW, Inc., Cleveland, OH, February 1981.

F. Galasso, M. Salkind, D. Kuehl, and V. Patarni:Trans. TMS-AIME, 1966, vol. 236, p. 1747.

M. Basche, R. Fanti, and F. Galasso:Fiber Science and Technology, 1968, vol. 1, p. 19.

G.A. Cooper and A. Kelly:J. Mech. Phys. Solids, 1967, vol. 15, p. 279.

L.E. Dardi and K.G. Kreider:Failure Modes in Composites I, I. Toth, ed., TMS-AIME, New York, NY, 1973, p. 231.

Author information

Authors and Affiliations

Additional information

The latter currently on

The latter currently on

Rights and permissions

About this article

Cite this article

Skinner, A., Koczak, M.J. & Lawley, A. Work of fracture in aluminum metal-matrix composites. Metall Trans A 13, 289–297 (1982). https://doi.org/10.1007/BF02643319

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF02643319