Abstract

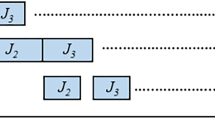

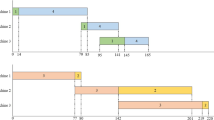

Detailed scheduling of a packing system, found in the process industry, is considered. The system consists of a number of packing lines which can pack several products in different formats (sizes). A size/product combination is called an item. Packing rates depend on both item and line. There are minor and major changeovers. The former occur between items of the same size; the latter between sizes. The lines are operated by operators whose number is limited. The number of products that can be packed at the same time in the packing room may be restricted by the number of material handling systems.

The objective of the scheduling is to pack item lots dictated by a medium-term planning system so that high packing rates and minimum changeover times are obtained.

The problem is formulated as a mixed-integer linear programming problem. The solution procedure is based on searching the solution space with the aid of low bounds derived from solving two subproblems: a machine loading subproblem formulated and solved as a general assignment problem, and a sequencing subproblem formulated and solved as finding the shortest arborescence in a directed network. Penalties to strengthen the low bounds are also devised and used.

Case studies to assess the efficiency and efficacy of the scheduling system are presented.

Similar content being viewed by others

References

E. Toczylowski, K. Nowosad, H. Jagdev and K. S. Hindi, “Aggregate lot-size scheduling for a class of two-stage production systems,”Large Scale Systems, vol. 11, no. 2, pp. 165–175, 1986.

T. Prabhakhar, “A production scheduling problem with sequencing considerations,”Management Science,21, pp. 34–43, 1974.

A. M. Geoffrion and G. W. Graves, “Scheduling parallel production lines with changeover considerations,”Operations Research,24, pp. 595–610, 1976.

R. G. Parker, R. H. Deane and R. A. Holmes, “On the use of a vehicle routing algorithm for the parallel processor problem with sequence dependent changeover costs,”AIIE Transactions,9, pp. 155–160, 1977.

R. R. Love Jr and R. R. Vegumanti, “The single plant mold allocation problem with capacity and changeover restrictions,”Operations Research,26(1), pp. 156–165, 1978.

M. L. Fisher, “The Lagrangean relaxation method for solving integer programming problems,”Management Science,27(1), pp. 1–18, 1981.

L. Chamlet and L. Gelders, “Lagrangean relaxation for a generalised assignment type problem”, in M. Roubens (ed.),Advances in Operations Research, North Holland, pp. 103–109, 1977.

G. T. Ross and R. M. Soland, “A branch and bound algorithm for the general assignment problem,”Mathematical Programming,8, pp. 91–103, 1975.

R. Nauss, “An efficient algorithm for the knapsack problem,”Management Science 23(1) pp. 27–31, 1976.

E. Edmonds, “Optimum branchings,”Journal of Research, National Bureau of Standards,71B, pp. 233–240, 1967.

D. R. Fulkerson, “Packing rooted directed cuts in a weighted directed graph,”Mathematical Programming,6, pp. 1–13, 1974.

R. E. Tarjan, “Finding optimum branchings,”Networks,7, pp. 25–35, 1977.

K. Belarbi and K. S. Hindi, “Detailed scheduling for a class of two-stage intermittent manufacturing systems,”Production Planning and Control,3 pp. 36–47, 1992.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Hindi, K.S., Belarbi, K. Detailed scheduling of a packing system. Int J Adv Manuf Technol 7, 218–224 (1992). https://doi.org/10.1007/BF02601627

Accepted:

Issue Date:

DOI: https://doi.org/10.1007/BF02601627