Abstract

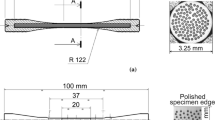

Fiber-reinforced titanium matrix composites (TMCs) are among the advanced materials being considered for use in the aerospace industry due to their light weight, high strength, and high modulus. A rapid infrared joining process has been developed for the joining of composites and advanced materials. Rapid infrared joining has been shown not to have many of the problems associated with conventional joining methods. Two models were utilized to predict the joint evolution and fiber reaction zone growth. Titanium matrix composite, 16-ply SCS-6/β21S, has been successfully joined with total processing times of approximately 2 minutes, utilizing the rapid infrared joining technique. The process utilizes a 50 °C/s ramping rate, 17-µm Ti-15Cu-15Ni wt pct filler material between the faying surfaces; a joining temperature of 1100 °C; and 120 seconds of time to join the composite material. Joint shear-strength testing of the rapid infrared joints at temperatures as high as 800 °C has revealed no joint failures. Also, due to the rapid cooling of the process, no poststabilization of the matrix material is necessary to prevent the formation of a brittle omega phase during subsequent use of the TMC at intermediate temperatures, 270 °C to 430 °C, for up to 20 hours.

Similar content being viewed by others

References

D.R. Tenney, W.B. Lisagor, and S.C. Dixon:NASA Technical Memorandum 101501, NASA, Oct. 1988.

B. Irving:Weld. J., 1991, vol. 70, pp. 65–67.

J.H. Devletian:Weld. J., 1987, vol. 6, p. 33.

J.S. Ahearn, C. Cooke, and S.G. Fishman:Met. Constr., 1982, vol. 14, p. 192.

T. Iseki, T. Kameda, and T. Maruyama:J. Mater. Sci., 1984, vol. 19, p. 1692.

J.R. Kennedy:Weld. J., 1973, vol. 52, pp. 120s-124s.

P.G. Partrige and C.M. Ward-Close:Met. Mater., 1989, vol. 5 (6), pp. 334–39.

D.M. Goddard, R.T. Pepper, J.W. Upp, and E.G. Kendall:Weld. J., 1972, vol. 51, pp. 178s-182s.

A. Hirose, M. Kotoh, S. Fukumoto, and K.F. Kobayashi:Mater. Sci. Technol., 1992, vol. 8, pp. 811–15.

I.W. Hall and J.-L. Lirn:J. Mater. Sci., 1992, vol. 27, pp. 3835–42.

A. Hirose, Y. Matshuhiro, M. Kotoh, S. Fukumoto, and K.F. Kobayashi:J. Mater. Sci., 1993, vol. 28, pp. 349–55.

E. Hoffman, R. Bird, and D. Dicus:Proc. American Institute of Aeronautics and Astronatutics 4th Int. Aerospace Planes Conf., Orlando, FL, American Institute of Aeronautics and Aeronautics, The Aerospace Center, 370 L’Efant Promenade, SW, Washington, DC 20024-2518. Dec. 1–4, 1992, 1992, pp. 1–10.

C.A. Blue, R.A. Blue, and R.Y. Lin:Scripta Metall., 1995, vol. 32 (1), pp. 127–32.

C.A. Blue, R.A. Blue, and R.Y. Lin:Proc. Adv. Mater., 1994, Apr. pp. 21–28.

R.R. Wells:Weld. J., 1976, vol. 3 (1), p. 205.

R.E. Shalin and Y.K. Koverneristy:Titanium ’80 Science and Technology, H. Kimura and O. Izumi, eds., TMS-AIME, 1980, pp. 277–93.

P. Martineau, R. Pailler, M. Lahaye, and R. Naslain:J. Mater Sci., 1984, vol. 19 (8), p. 2749.

D.B. Gundel and F.E. Wawner:Scripta Metall., 1991, vol. 25, pp. 437–41.

J.L. Murray:Bull. Alloy Phase Diagram, 1981, vol. 2 (2), pp. 185–90.

K. Chaudhri and J.H. Perepezko:Metall. Mater. Trans. A, 1994, vol. 25A, pp. 1109–18.

E.W. Collings:The Physical Metallurgy of Titanium Alloys, ASM, Metals Park, OH, 1983, pp. 45–50.

T.W. Duerung and J.C. Williams:Beta Titanium in the 1980’s, R.R. Boyer and H.W. Rosenberg, eds., Warrendale, PA, AIME, 1984, pp. 19–67.

J.T. Niemann, S.R. Spear, J.L. McAfee, and W.L. Lewis:An Investigation of the Thermal Stability of Beta 21S Titanium Alloy to Determine Its Stability for Service on the NASP, Special Report, McDonnell Douglas Corp., St. Louis, MO, 1991.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Blue, C.A., Sikka, V.K., Blue, R.A. et al. Infrared transient-liquid-phase joining of SCS-6/β21S titanium matrix composite. Metall Mater Trans A 27, 4011–4018 (1996). https://doi.org/10.1007/BF02595650

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF02595650