Conclusions

On the basis of these calculations, the following conclusions were made.

In soft rocks (category IV) with relatively shallow blast holes (<2.5 m), wedge cuts ensure maximum efficiency.

As rock category number increases, explosives with higher shattering effect are recommended. Cartridged explosives are preferable for all rock categories to granulated materials.

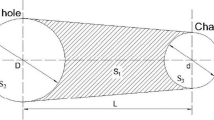

The solution of the optimization problem has established efficiency paths of the graph and the corresponding technical schemes for cut cavity formation (see Table 1).

The data in the table suggest that straight cuts with compensation holes should be used on an increasing scale in proportion to higher rock strength and blast hole depth.

The method makes it possible to compare the excavation cut configurations when preparing specifications for DBO, and select the most efficient configuration that provides, for a given HUF, reliable rock breaking characteristics.

Similar content being viewed by others

Literature Cited

G. G. Mukhtarov and V. M. Roginskii, Performance of Horizontal Mining Operations [in Russian], Nedra, Moscow (1984).

A. V. Boev, V. Ya. Shapiro, V. G. Ort, et al., “Improving drill and blast operations in workings with self-propelled equipment at Achinsk Polymetallic Ore Works,” Gorn. Zh., No. 9 (1986).

V. L. Rusakov, V. A. Khramtsov, O. P. Danilin, and S. G. Senkevich, “Analysis of efficiency of blasting and drilling in a working with self-propelled machines”, Gorn. Zh., No. 3 (1987).

I. M. Sobol' and R. B. Statnikov, Selection of Optimal Parameters in Multicriterion Problems [in Russian], Nauka, Moscow (1981).

V. Ya. Shapiro, A. V. Boev, and N. V. Litvinovich, “Improving the parameters of drilling and blasting operations in mine workings,” Gorn. Zh., No. 2 (1985).

V. Ya. Shapiro, “Classification of rocks according to explodability in tunneling operatins,” Fiz.-Tekh. Probl. Razrab. Polezn. Iskop., No. 3 (1988).

A Methodological Guide on Preparing Specifications for Drilling and Blasting Operations in Mining with Self-Propelled Equipment in Nonferrous Metal Deposits [in Russian], VNIItsvetmet, Ust-Kamenogorsk (1987).

S. Barsanaev, “Study of efficiency of charges in water-filled shells,” in: Explosive Rock Breaking [in Russian], Nedra, Moscow (1967).

E.I. Shemyakin, “Stress wave in strong rocks,” Probl. Mekh. Tekh. Fiz., No. 5 (1963).

A. N. Stavrogin, V. P. Sapunova, and T. V. Andreev, Atlas of Mechnical Properties of Rocks [in Russian], VNIMI, Leningrad (1968).

E. I. Rogov, “Method for isolating important variables in mathematical simulation of processes,” in: New Methods of Study in Mining [in Russian], Alma-Ata (1971).

V. Ya. Shapiro and B. V. Lozdnyakov, “Statistical method for calculation of drilling and blast operation parameters in mining,” Fiz.-Tekh. Probl. Razrab. Polezn. Iskop., No. 4 (1987).

Additional information

Institute of Nonferrous Metals, Ust-Kamenogorsk. Translated from Fiziko-Tekhnicheskie Problemy Razrabotki Poleznykh Iskopaemykh, No. 4, pp. 95–103, July–August, 1989.

Rights and permissions

About this article

Cite this article

Shapiro, V.Y. Efficiency of cut configuration in driving tunnels with a set of deep blast holes. Soviet Mining Science 25, 379–386 (1989). https://doi.org/10.1007/BF02528560

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF02528560