Abstract

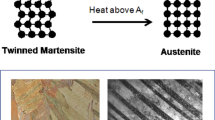

We consider a generalization of the synthesis model of irreversible deformation aimed at the description of the distinctive features and mutual influence of the processes of deformation caused by martensite transformations and defects. We describe programs of cyclic temperature and force loading used to realize the multiple reversible effect of memory of the shape and demonstrate the applicability of the model for the prediction of the deformation behavior of contemporary structural materials based on iron alloys.

Similar content being viewed by others

References

Ya. F. Andrusik and K. N. Rusinko, “Plastic deformation of hardening materials under loading in a three-dimensional subspace of the five-dimensional deviator space,”Izv. Ros. Akad. Nauk, Mekh. Tverd. Tela, No. 2, 92–101 (1993).

I. M. Goliboroda and K. N. Rusinko, “Description of reversible deformation caused by martensite transformations within the framework of the synthesis model,”Probl. Prochn., No. 8, 68–75 (1995).

I. M. Goliboroda and K. N. Rusinko, “Universal relationship between the intensities of tangential stresses and shear strains in the description of reversible martensitic deformation within the framework of the synthesis model,”Zh. Prikl. Mekh. Tekh. Fiz., No. 3, 178–185 (1996).

I. M. Goliboroda and K. N. Rusinko, “A phenomenological model of nonlinear deformation of polycrystalline bodies caused by martensite transformations,”Zh. Tekh. Fiz., No. 11, 124–135 (1996).

V. A. Likhachev, S. L. Kuz’min, and Z. P. Kamentsova,Effect of Memory of the Shape [in Russian], Leningrad University, Leningrad (1987).

D. M. Vasil’ev, “Microstresses formed in metals in the process of plastic deformation. Part 2,”Fiz. Tverd. Tela,1, 1736–1746 (1959).

V. A. Likhachev and V. G. Malinin,The Analytic Structural Theory of Plasticity [in Russian], Nauka, St. Petersburg (1993).

T. Breczko,Odkstalcenia Plastyczne Polikrystalow, Politechnika Bialostocka, Bialystok (1989).

V. V. Novozhilov and Yu. I. Kadashevich,Microstresses in Structural Materials [in Russian], Mashinostroenie, Leningrad (1990).

K. N. Rusinko,Distinctive Features of Inelastic Deformation of Solids [in Russian], Vyshcha Shkola, Lvov (1986).

K. Tanaka, T. Hayashi, F. Nishimura, and H. Tobushi, “Hysteresis behavior in an Fe−Cr−Ni−Mn−Si polycrystalline shape-memory alloy during thermomechanical cyclic loading,”J. Mater. Eng. Perform.,3, No. 2, 135–143 (1995).

Additional information

“L’vivs’ka Politekhnika” State University, Lvov, Ukraine. Translated from Problemy Prochnosti, No. 6, pp. 124–131, November–December, 1998.

Rights and permissions

About this article

Cite this article

Goliboroda, I.M. Description of the mutual influence of processes of deformation of different physical nature in terms of a synthesis model. Strength Mater 30, 651–657 (1998). https://doi.org/10.1007/BF02523173

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF02523173