Conclusions

-

1.

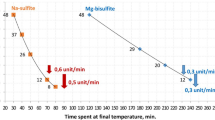

It has been established that the degree of effect of the duration of pulp magnetization on its deposition rate depends on the intensity of the field in which magnetization and dilution of the magnetization and dilution of the magnetized product are effected.

-

2.

The interrelation of the H and t factors is such that the effect of the magnetization duration on the pulp deposition rate increases with the field intensity.

-

3.

It has been found that the t range in which the duration has an effect on pulp flocculation varies with the field intensity.

-

4.

At sufficiently high intensities (more than 48–50 kA/m) the magnetization duration factor is very important and is often the only means of increasing the deposition rate of the flocculated pulp. This must be taken into account when it is necessary to speed up the deposition rate of diluted magnetized pulps.

-

5.

Comparison of the results with practical pulp magnetization data (H=40–48 kA/m, t=0.15–0.2 sec) enables us to infer that the pulp magnetization time should be increased to 0.4–0.5 sec.

Similar content being viewed by others

Literature Cited

V. G. Derkach and T. N. Galevskaya, “Magnetization and demagnetization of magnetite and ferrosilicium,” Gorn. Zh., No. 2 (1958).

K. N. Lymar', “The effect of magnetic coagulation on wet sizing during beneficiation of finely crushed magnetite ores,” Nauch.-Tekhn. Byull. “Mekhanobr,” No. 3 (1956).

W. H. Benson, J. A. Bartnik, and G. D. Rose, “Demagnetizing coils and magnetic flocculators used in magnetite beneficiation,” Mining Engng.,20, No. 8, 58–61 (1968).

V. G. Derkach and K. N. Lymar', “Magnetic coagulation of finely disseminated magnetite ores and its effect on beneficiation,” Gorn. Zh., No. 12 (1955).

V. V. Karmazin, V. I. Karmazin, and V. A. Vinkevich, Magnetic Regeneration and Separation during Beneficiation of Ores and Coal [in Russian], Nedra, Moscow (1968).

V. P. Nikolaenko, Precipitation of Magnetized Pulps [in Russian], Izd. UkrNIINTI, Kiev (1969).

V. V. Nalimov and V. A. Chernova, Statistical Methods of Planning Extremal Experiments [in Russian], Nauka, Moscow (1965).

L. M. Batuner and P. E. Pozin, Mathematical Methods in Chemical Technique [in Russian], Goskhimizdat. Moscow (1960).

Additional information

Dnepropetrovsk Mining Institute. Translated from Fiziko-Tekhnicheskie Problemy Razrabotki Poleznykh Iskopaemykh, No.2, pp. 79–86, March–April, 1970.

Rights and permissions

About this article

Cite this article

Karmazin, V.I., Nikolaenko, V.P. How the duration of magnetic treatment affects the deposition rate of magnetized magnetite pulp. Soviet Mining Science 6, 195–200 (1970). https://doi.org/10.1007/BF02502159

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF02502159