Summary

-

1.

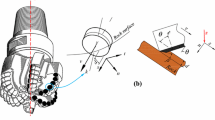

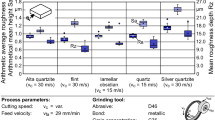

The most effective tool from the point of view of strength and power requirement is one with a trapezoidally shaped cutting edge with transition face angles of 45°.

-

2.

Tools with square cutting edges require the least energy but do not meet strength requirements.

-

3.

Rounding-off the cutting edges of the tool reduces specific tool wear but raises the power requirement in cutting slightly.

-

4.

Increasing the width of tool blade in contact with the rock to 50 mm reduces wear intensity and the power requirement in cutting, especially if we use an interrupted cutting edge the adjacent blades of which exert mutual effects during the breaking of rocks of medium hardness.

0

Similar content being viewed by others

Literature Cited

A. I. Beron, A. S. Kazanskii, B. M. Leibov, and E. Z. Pozin, Coal Cutting [in Russian], Gosgortekhizdat, Moscow (1962).

A. N. Zelenin, Soil Cutting [in Russian], Izd. AN SSSR, Moscow (1959).

V. N. Getopanov, Some regularities of rock breaking with a cutting tool, Coll.: Moscow Mining Symposium, no. 21, Izd. MGU, Moscow (1957).

L. I. Baron, L. B. Glatman, and L. A. Khripina, The effect of the shape of the cutting edge and the front face of the bit on tool wear and forces in rock cutting.

V. G. Mikhailov, M. G. Simileiskii, É. V. Rylev, and B. M. Shamshin, Study and selection of bits for rock drills, Trans. Novocherkassk Polytech. Inst., Vol. 80, No. 1, Novocherkassk (1959).

Yu. P. Linenko, On the theory of rotary bit operation, Coll.: Diamond and Hand Alloy Tools in Mining, Tekhnika, Kiev (1965).

N. E. Cherkasov, Study of stresses on cutting tools in mechanized tunnel panels, Coll.: Laboratory and Industrial Research in Mechanized Rock Working in Bulding Subway Tunnels, Izd. TsNIIS Mintransstroya, Moscow (1959).

A. L. Polyak and É. I. Isakov, Results of laboratory research in breaking rocks with strengths up to f=10 on the scale of M. M. Protod'yakov, Tr. UkrNIIOMShSa, No. 14, Gosgortekhizdat, Moscow (1962).

M. G. Krapivin, G. G. Garyuk, K. B. Kogan, and V. D. Sukach, Cutting-tool consumption in tests of an experimental rock-cutting combine, Coll.: Results of Studies of Tools and Working Elements of Rock-Cutting Combines, Izd. TsITIUglya, Moscow (1962).

G. G. Garyuk, M. G. Krapivin, É. V. Rylev, and V. M. Dubyanskii, On selecting a grade of hard alloy for reinforcing the blades of rock-cutting combines, Ibid..

B. M. Loguntsov and Z. N. Alekhova, Rock breaking with cutting tools reinforced with various grades of hard alloys, Trans. Conf. on Coal and Rock Breaking, Vysshaya Shkola, Moscow (1963).

L. I. Baron, L. B. Glatman, and E. K. Gubenkov, Criteria and Methods for Measuring the Wear of Rock-Cutting Tools, Izd. Inst. Gornogo Dela im. A. A. Skochinskogo (1961).

Additional information

L. N. Virovets and D. M. Miflig also participated in this work.

Institute of Superhard Materials, Kiev. Translated from Fiziko-Tekhnicheskie Problemy Razrabotki Poleznykh Iskopaemykh, No. 4, pp. 77–84, July–August, 1967.

Rights and permissions

About this article

Cite this article

Linenko, Y.P., Karyuk, G.G. The shape and dimensions of the cutting edges of rock tools. Soviet Mining Science 3, 380–385 (1967). https://doi.org/10.1007/BF02497563

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF02497563