Abstract

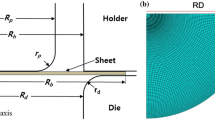

Flange earrings of strong anisotropic sheet metals in deep-drawing process are numerically analyzed by the elastic-plastic large deformation finite element formulation based on a discrete Kirchhoff triangle plate shell element model. A Barlat-Lian anisotropic yield function and a quasi-flow corner theory are used in the present formulation. The numerical results are compared with the experimental ones of cylindrical cup drawing process. The focus of the present researches is on the numerical analysis and the constraining scheme of the flange earring of circular sheets with strong anisotropy in square cup drawing process.

Similar content being viewed by others

References

Hu P, Lian J, Liu YQ, et al. A quasi-flow corner theory of elastic plastic finite deformation.Int J Solids Struct, 1998, 35(15): 1827

Christofferson J, Hutchinson JW. A class of phenomenological corner theories of plasticity.J Mech Phys Solids, 1979, 27: 465

Needleman A, Tvergaard V. Necking of biaxially stretched elastic-plastic circular plates.J Mech Phys Solids, 1977, 25: 159

Gotoh M. A class of plastic constitutive equations with vertex effect—I. General theory.Int J Solids Struct, 1985, 21(11): 101

Barlat F, Lian J. Plastic behavior and stretch-ability of sheet metals. Part I: A yield function for orthotropic sheet under plane stress conditions.Int J Plasticity, 1989, 5: 51

Bishop JWF, Hill R. A theory of the plastic distortion of a polycrystalline aggregate under combined stress.Phil Mag, 1951, 42: 414

Hu P, Na JX, Li DY. Bifurcation and post bifurcation behavior in sheet metal tension with strong anisotropy.J Mater Proc Tech, 1998, 74: 276

Gotoh M. A finite element analysis of the rigid-plastic deformation of the flange in a deep-drawing process based on a fourth-degree yield function—II.Int J Mech Sci, 1980, 22: 367

Batoz JL, Bathe KJ, Ho LW. A study of three-node triangular plate bending elements.Int J Num Meth Engng, 1980, 15: 1771

Author information

Authors and Affiliations

Additional information

The project supported by the National Natural Science Foundation of China (19832020) and Provincial Natural Science Foundation of Jilin, China (200000519)

Rights and permissions

About this article

Cite this article

Yuqi, L., Jincheng, W. & Ping, H. A finite element analysis of the flange earrings of strong anisotropic sheet metals in deep-drawing processes. Acta Mech Sinica 18, 82–91 (2002). https://doi.org/10.1007/BF02487526

Received:

Revised:

Issue Date:

DOI: https://doi.org/10.1007/BF02487526