Abstract

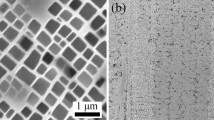

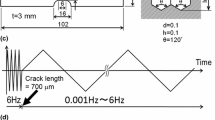

Micron-sized internal cracks were introduced into rounded bars of pure iron by low cycle fatigue, and the cracks had irregular penny-shaped morphology with the critical diameter of about 30μm and the thickness of 0.5–1.5μm. The initiation and propagation of the cracks were investigated quantitatively as well as their location and geometry. After vacuum annealing of the samples fatigued, the morphology in a two-dimensional longitudinal section of cracks within grains had evolved from initially elliptical one into arrays of spherical voids controlled by surface diffusion. Furthermore, a typical morphology for a broken crack with a center spherical void surrounded by outer doughnut-like cavities was observed along a perpendicular section of the specimen. Subsequently the spherical voids shrink and diminish gradually dominated by bulk diffusion. A physical model to heal an internal microcrack was proposed, in particular for the various healing stages controlled by the related dominant diffusion mechanism and their dependencies upon the morphology and geometry of an original micro-crack in materials.

Similar content being viewed by others

References

Wiederhorn SM, Townsend PR. Crack healing in glass.J Am Ceram Soc, 1970, 53(9): 486–489

Evans AG, Charles EA. Strength recovery by diffusive crack healing.Acta Metall, 1977, 25(8): 919–925

Smith DL, Evans B. Diffusional crack healing in quartz.J Geophys Res, 1984, 89(B6): 4125–4135

Zhou YZ, Zeng Y, He GH, et al. The healing of quenched crack in 1045 steel under electropulsing.J Mater Res, 2001, 16(1):17–19

Yen CF, Coble RL. Spheroidization of tubular voids in Al2O3 crystals at high temperature.J Am Ceram Soc, 1972, 55(10): 507–509

Gupta TK. Instability of cylindrical voids in alumina.J Am Ceram Soc, 1978, 61(5–6): 191–195

Ackler HD. Healing of lithographically introduced cracks in glass and glass-containing ceramics.J Am Ceram Soc, 1998, 81(12): 3093–3103

Nichols FA. On the spheroidization of rod-shaped particles of finite length.J Mater Sci, 1976, 11(6): 1077–1082

Gittins A. The stability of grain boundary cavities in copper.Acta Metall, 1968, 16(4): 517–522

Takahashi Y, Inoue K, Nishiguchi K. Identification of void shrinkage mechanisms.Acta Metall Mater, 1993, 41(11): 3077–3084

Nichols FA, Mullins WW. Surface-(interface-) and volume-diffusion contribution to morphological changes driven by capillarity.Trans Metall Soc AIME, 1965, 233(10): 1840–1847

Sommer C, Mughrabi H, Lochner D. Influence of temperature and carbon content on the cyclic deformation and fatigue behaviour of α-iron. Part II: Crack initiation and fatigue life.Acta Mater, 1998, 46(5): 1537–1546

Herring C. Effect of change of scale on sintering phenomena.J Appl Phys, 1950, 21(4): 301–303

Huang PZ, Li ZH, Sun J. Shape evolution of penny-shaped microcrack controlled by surface diffusion.Acta Mechanica Sinica, 2002, 34(3): 344–350 (in Chinese)

Marich S, Jaffrey D. The morphology and thermal stability of the Cu−Cu2S eutectic system.Metall Trans, 1971, 2(9): 2681–2689

Rayleigh L. On the instability of jets.Proc London Math Soc, 1878, 10: 4–13

Sun J. A model for shrinkage of a spherical void in the center of a grain: Influence of lattice diffusion.J Mat Engng & Performance, 2002, 11(3): 322–331

Author information

Authors and Affiliations

Additional information

The project supported by the National Outstanding Young Investigator Grant of China (59925104) and the National Natural Science Foundation of China (59889101)

Rights and permissions

About this article

Cite this article

Hailong, Z., Jun, S. Morphological evolution during diffusive healing of internal cracks within grains of α-iron. Acta Mech Sinica 18, 516–527 (2002). https://doi.org/10.1007/BF02486576

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF02486576