Abstract

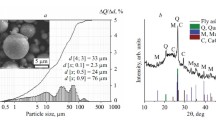

Mixtures of fly ash, bottom ash and Flue Gas Desulphurized (FGD) gypsum, all solid wastes from coalfired electric generating plants, can be combined with lime and 10% of water to produce a damp powder which can be moulded at a pressure of 20–40 MPa and then steam-cured in less than 1 day at 35–80°C. The resulting building materials-in the form of bricks, blocks or slabs-produced by this Pressure Forming (PF) process, are stronger and sounder than the corresponding materials produced by a slip casting (SC) process.

The physical and mechanical properties of the materials manufactured through the PF process are based on the reaction of amorphous silica and alumina of the ash with lime or lime and gypsum respectively, so that calcium silicate hydrate and ettringite are produced. When the temperature of the steam curing is as low as 35°C, the hardened material is sound in the air, but it swells and is quickly destroyed by the action of water. This effect can be ascribed to the formation of ill-crystallized ettringite. On the other hand, with thermal treatment at higher temperatures (60–80°C), the material is stronger and sound even in the presence of water in service. The well-crystallized ettringite fibers, favoured by the higher temperature of the steam curing treatment, are considered to be responsible for the better mechanical performances and the lower change in length.

In general, the physical and mechanical properties of the ash-gypsym-lime cementitious system are better than those of the traditional clay-based ceramic products manufactured at temperatures as high as 1000°C. Therefore, this process based on steam curing at 60–80°C appears to be very useful for both the re-utilization of solid wastes and the saving of energy in the production of building materials.

Résumé

Un mélange de cendres volantes et de gypse provenant d'installations de désulfuration, déchets solides dérivés de la combustion du charbon dans les centrales thermoélectriques, peut être combiné avec de la chaux et de l'eau (dans un rapport de 10% environ) pour produire une poudre humide qui peut être comprimée à 20–40 MPa et soumise à un étuvage (35–80°C) pour une durée inférieure à 24 heures.

Le matériau de construction résultant, briques, blocs ou plaques, obtenu par cette mise en œuvre sous pression est plus résistant qu'un matériau analogue produit par coffrage glissant.

Les propriétés physiques et chimiques du matériau produit par mise en œuvre sous pression dépendent de la réaction entre la silice amorphe et l'alumine contenues dans les cendres et, respectivement, la chaux ou la chaux et le gypse, ce qui entraîne une formation de silicate de calcium hydraté et d'ettringite. Quand la température d'étuvage est faible (par exemple 35°C), le matériau durcit et est stable à l'air mais il se produit un gonflement entraînant la destruction rapide sous l'action de l'eau. Cette dégradation peut être due à la formation d'une ettringite amorphe ou mal cristallisée. Au contraire, quand l'étuvage est conduit à température plus élevée (60–80°C), le matériau est plus résistant et n'est plus attaqué par l'eau. La formation d'ettringite bien cristallisée, grâce à la température plus élevée de l'étuvage, est responsable des meilleures performances mécaniques et d'une plus grande stabilité dimensionnelle du matériau.

En général, les propriétés physiques et mécaniques du système cendre-gypse-chaux sont meilleures que celles des briques traditionnelles produites à des températures d'environ 1000°C. Donc, le procédé proposé, basé sur un traitement thermique à 60–80°C, semble être valable autant pour la réutilisation des déchets que pour les économies d'énergie dans la production des matériaux de construction.

Similar content being viewed by others

References

Yeager, K., ‘Aqueous discharge monitoring and treatment’,Electric Power Research Institute Journal,9 (4) (1984) 44–49.

Mc Carthy, G. J. and Solem-Tishmack, J. K. ‘Hydration mineralogy of cementitious coal combustion by-products’,in «Advances in Cement and Concrete», Proceedings of an Engineering Foundation Conference, Durham, July 1994 (Ed. by M. W. Grutzeck and S. L. Sakar, ASCE) pp. 103–121.

Ikeda, K. and Tomisaka, T. ‘Fundamental studies on the preparation and strength of steam-cured porous materials made from mixture of fly ash, gypsum and lime’,Journal Ceramic Japanese Society,97 (1989) 468–474.

Collepardi, M. ‘Mechanism of deterioration and mix design of durable concrete structures’, in ‘P. K. Mehta Symposium’, Proceedings of an International Conference, Nice, May 1994 (Ed. by K. H. Khayat and P. C. Aitcin) pp. 35–60.

Mehta, P. K., ‘Mechanism of expansion associated with ettringite formation’,Cement and Concrete Research,3 (1973) 1–6.

Collepardi, M., Coppola, L. and Pistolesi, C., ‘Durability of concrete structures exposed to CaCl2 based deicing salts’,in ‘Durability of Concrete’, Proceedings of the Third CANMETACI International Conference on Durability of Concrete, Nice, May 1994 (Ed. by V. M. Malhotra) pp. 107–120.

Author information

Authors and Affiliations

Additional information

Editorial note Prof. Mario Collepardi is teaching at the Dipartimento di Scienza dei Materiali e della Terra, Universita degli Studi di Ancona, which is a RILEM Associate Member. Prof. Collepardi is a member of the Board of Advisors forMaterials and Structures. Eng. Giulio Belz is a RILEM Senior Member.

Rights and permissions

About this article

Cite this article

Coppola, L., Belz, G., Dinelli, G. et al. Prefabricated building elements based on FGD gypsum and ashes from coal-fired electric generating plants. Mat. Struct. 29, 305–311 (1996). https://doi.org/10.1007/BF02486365

Issue Date:

DOI: https://doi.org/10.1007/BF02486365