Abstract

This is the first part of two papers on the experimental (Part I) and theoretical (Part II) resistance of steel fibre reinforced precast concrete beams.

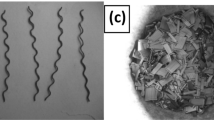

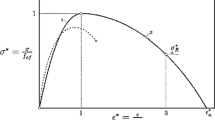

Short steel fibres have been introduced into prestressed concrete X beams in order to study their behaviour under shear loads. The X beams, which have circular web profiles, were chosen to represent longitudinal sections from 215 mm deep prestressed precast hollow cored floor units, which are known to fail in shear in a brittle manner. No shear links were used. Round hooked end high strength steel (HS), and thin amorphous metal (AM) fibres were used in volume fractions up to 2.0%. The maximum flexural strength of fibre reinforced concrete (FRC) was 10.28 N/mm2, some 50% greater than plain concrete. In the plain concrete beams the ratio η of the ultimate shear resistance to the cracking resistance was 1.0, as expected. For the fibre beams η=1.43 to 1.52 for the HS fibres and η-1.23 for the AM fibres. Theoretical and empirical equations were developed using modified FRC principal tensile stress methods to predict ultimate shear strength and are given in Part II.

Résumé

Il s'agit de la première partie d'un article sur la résistance des poutres en béton préfabriqué renforcé de fibres d'acier, présentant les expériences (partie I) et la théorie (partie II).

De courtes fibres d'acier ont été utilisées dans des poutres X précontraintes pour étudier leur comportement sous l'action de forces de cisaillement. Les poutres X, qui ont des âmes de profil circulaire, ont été choisies pour représenter des sections longitudinales des dalles alvéolées précontraintes de 215 mm d'épaisseur, qui sont connues pour leur mode de rupture casant sous l'action des efforts tranchants. L'armature de cisaillement n'a pas été utilisée. Des crochets ronds en acier à haute adhérence et de minces fibres métalliques amonrphes ont été utilisés jusqu'à des fractions de 2% du volume. La résistance à la tension maximale sous l'effet de flexion du béton de fibres d'acier était de 10,28 N/mm2, soit 50% de plus que pour le béton normal. Pour les poutres en béton normal, le rapport η entre la résistance ultime au cisaillement et la résistance à la fissuration était de 1,0, comme prévu. Pour les poutres en fibres d'acier ce rapport était entre 1,43 et 1,52 pour l'acier à haute adhérence et 1,23 pour les fibres métalliques amorphes. Des équatins théoriques et empiriques ont été développées à l'aide de méthodes de contrainte de tension principlale du béton de fibres d'acier modifiées pour la prédiction de la résistance ultime au cisaillement; celles-ci sont données dans la deuxième partie.

Similar content being viewed by others

References

Eurocode 2: ‘Design of Concrete Structures—Part 1: General Rules and Rules for Buildings’, EN 1992-1-1 (2001).

Narayanan, R. and Kareem-Palanjian, A. S., ‘Effect of fibre addition on concrete strengths’,Indian Concrete Journal 58 (4) (1984) 100–103.

Nanni, A., ‘Splitting tension test for fiber reinforced concrete’,ACI Materials Journal 85 (4) (1988) 229–233.

Paine, K. A., ‘Steel fibre reinforced concrete for prestressed hollow core slabs’, Ph. D. Thesis, University of Nottingham, UK (1998).

BS 12, ‘Specification for Portland Cements’, British Standards Institution (1991).

BS 3892, Part 1, ‘Specification for Pulverized-Fuel Ash for use with Portland Cement’, British Standards Institution, London (1993).

BS 882, ‘Specification for Aggregates from Natural Sources for Concrete’, British Standards Institution, London (1992).

Rossi, P., ‘Mechanical behaviour of metal-fiber reinforced concretes’,Cement and Concrete Composites 14 (1992) 3–16.

BS 1881, ‘Methods of Testing Concrete’, British Standards Institution, London (1983).

American Concrete Institute, Committee 544, ‘Measurement of properties of fiber reinforced concrete’, ACI 544.2R-88,ACI Materials Journal 85 (6) (1988) 583–593.

Japan Concrete Institute, ‘Method of Test for Flexural Strength and Flexural Toughness of Fiber Reinforced Concrete’, JCI Standard SF4, JCI Standards for Test Methods of Fiber Reinforced Concrete (1983) 35–36.

Bentur, A. and Mindess, S., ‘Fibre Reinforced Cementitious Composites’ (Elsevier Applied Science 1990).

Lanu, M., ‘Testing fibre-reinforced concrete in some structural applications’, Report No. 237, Technical Research Centre of Finland, Espoo, Finland (1995).

BS 5896, ‘Specification for High Tensile Steel Wire and Strand for the Prestressing of Concrete’, British Standards Institution, London (1980).

Girhammar, U.-A., ‘Design principles for simply-supported prestressed hollow core slabs’,Structural Engineering Review 4 (4) (1992) 301–316.

Peaston, C. H., Elliott, K. S. and Paine, K. A., ‘Steel fiber reinforcement for extruded prestressed hollow core slabs’, in ACI SP 182—Structural Applications of Fiber Reinforced Concrete (1999) 87–107.

BS 8110, ‘Structural Use of Concrete, Part 1, Code of Practice for Design and Construction’, British Standards Institution, London (1985).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Elliott, K.S., Peaston, C.H. & Paine, K.A. Experimental and theoretical investigation of the shear resistance of steel fibre reinforced prestressed concrete X-beams—Part I: Experimental work. Mat. Struct. 35, 519–527 (2002). https://doi.org/10.1007/BF02483119

Received:

Accepted:

Issue Date:

DOI: https://doi.org/10.1007/BF02483119