Abstract

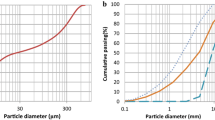

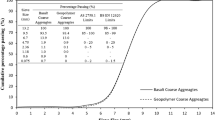

Two high-strength concretes (HSC) only differing in their aggregates—silico-calcareous and hematite—were heated at temperatures up to 450°C (1°C/min). The evolution of their microstructural parameters—porosity, pore structure, permeability—were analysed. Both concretes showed equivalent initial microstructural characteristics. From 60°C, heating generated a large capillary porosity characterized by pore accesses around 0.1 μm. The intensity and especially the width of the porosity peaks increased with temperature. For silico-calcareous HSC, macropores-50 to 0.3 μm—were detected by MIP studies at 250°C and especially at 450°C. They were correlated to microcracks visually observed at the surface of the probes. Up to 250°C, the intrinsic permeability increased similarly for both concretes. Between 250 and 450°C, permeability remained stable for hematite HSC while, for silico-calcareous HSC, a major change was noticed. A good correlation between permeability and total water porosity was observed. At 450°C, influence of the microcracks on permeability was greater than the impact of the increase of capillary pore size. As both concretes showed similar initial microstructural features, conclusion was reached that the differential behaviour can mainly be attributed to internal thermal gradients discrepancies related to the type of aggregates: hematite allows to limit thermal gradient and thus, thermo-mechanical stresses. It was globally observed that damage due to high temperature thermal treatments was lower for hematite HSC.

Résumé

Deux bétons à hautes performances se distinguant uniquement par leurs granulats—silico-calcaires et hématites—ont subi des traitements thermiques allant jusqu'à 450°C (1°C/min). L'évolution de leurs propriétés microstructurales —porosité, structure des pores, perméabilité—a été examinée. Initialement, les caractéristiques microstructurales des deux bétons sont identiques. Dès 60°C, le chauffage provoque l'apparition d'une importante porosité capillaire dont les accès de pore se situent au voisinage de 0,1 μm. L'intensité et surtout la largeur des pics de porosité augmentent avec la température. Pour le béton silico-calcaire, des macropores—dans la gamme 50 à 0.3 μm—ont également été mis en évidence par la porosimétrie mercure à partir de 250°C et surtout à 450°C. Ceux-ci ont été corrélés à des microfissures détectées visuellement à la surface des éprouvettes. Jusqu'à 250°C, on observe pour les deux bétons une augmentation de la perméabilité au gaz. Entre 250 et 450°C, ce paramètre n'évolue pas pour le béton d'hématite alors qu'une évolution majeure est de nouveau observée pour le béton silico-calcaire. Ces évolutions sont bien corrélées à celles de la porosité totale à l'eau. En tenant compte de la similitude microstructurale initiale de la phase cimentaire des deux bétons, cette différence de comportement a été principalement attribuée à des différences de gradients thermiques internes liées au type de granulats, l'hématite permettant de limiter les gradients thermiques et par conséquent les contraintes d'origine thermo-mécaniques. Globalement, l'endommagement lié aux traitements thermiques est moins conséquent pour le béton d'hématite.

Similar content being viewed by others

References

Riley, M. A., ‘Possible new method for the assessment of fire-damaged concrete’,Mag. Concr. Res. 43 (155) (1991) 87–92.

Phan, L. T., Carino, N. J., Duthin, D. and Garboczi, E., ‘Fire performance of high-strength concrete’, NIST Proceedings of the Int. Workshop, NIST Special Publication 919, Gaithersburg, Maryland, USA (1997).

Castillo, C. and Durrani, A. J., ‘Effect of transient high temperature on high-strength concrete’,ACI Mat. J. 87 (1) (1990) 47–53.

Sanjayan, G. and Stocks, L. J., ‘Spalling of high-strength silica fume concrete in fire’,ACI Mat. J.,90 (2) (1993) 170–173.

Saad, M., Abo-El-Enein, S. A., Hanna, G. B. and Kotkata, M. F., ‘Effect of silica-fume on the phase composition and microstructure of thermally treated concrete’,Cem. Concr. Res. 26 (10) (1996) 1479–1484.

Chan, Y. N., Peng, G.-F. and Chan, K. W., ‘Comparison between high strength concrete and normal strength concrete subjected to high temperature’,Mater. Struct. 29 (1996) 616–619.

Tsimbrovska, M., Kalifa, P., Quenard, D. and Daian, J.-F. ‘High performance concretes at elevated temperature: permeability and microstructure’, Transactions of the 14th International Conference on Structural Mechanics in Reactor technology (SmiRT 14), Lyon, France, 1997, 475–482.

Kalifa, P., Tsimbrovska, M. and Baroghel-Bouny, V., ‘High-performance concrete at elevated temperatures—An extensive experimental investigation of thermal and hygral properties and microstructure’, Proceedings of Int. Symp. on High-Performance and Reactive Powder Concretes, Sherbrooke, Canada, 1998, 259–279.

Kalifa, P., Mennenteau, F.-D. and Quenard, D., ‘Spalling and pore pressure in HSC at high temperatures’,Cem. Concr. Res. 30 (2000) 1–13.

Ulm, F.-J., Acker, P. and Levy, M., ‘The clunnel, fire. II: analysis of concrete damage’,ASCE J. Eng. Mech. 125 (3) (1999) 283–289.

Noumowé, A., ‘Effet de hautes températures sur le béton. Cas particulier du béton à hautes performances’, PhD-Thesis (in French), INSA Lyon, France, (1995).

Bažant, Z. P. and Thongutai, W., ‘Pore pressure and drying of concrete at high temperature’,J. Eng. Mech. Div. ASCE 104 (1978) 1058–1080.

Bažant, Z. P. and Kaplan, M. F., ‘Concrete at high temperatures. Material properties and mathematical models’, (Longman House, Burnt Mill, England, 1996).

Khoury, G. A., ‘Compressive strength of concrete at high temperatures: a reassessment’,Mag. Concr. Res. 44 (161) (1992) 291–309.

Gallé, C, Sercombe, J., Pin, M., Arcier, G. and Bouniol, P., ‘Behaviour of high performance concrete under high temperature (60–450°C) for surface long-term storage: thermo-hydromechanical residual properties’, MRS Conference, Sydney, Australia, 27–31 August, 2000.

Bouniol, P., ‘Structures des réacteurs nucléaires. Bétons spéciaux de protection’, in ‘Les Techniques de l'Ingénieur’ (in French), Génie Nucléaire, Article BN 3740.

Gallé, C. and Daian, J.-F., ‘Gas permeability of unsaturated cement based materials: application of a multiscale network model’,Mag. Concr. Res. 52 (4) (2000) 251–263.

Klinkenberg, L. J., ‘The permeability of porous media to liquids and gases’, API Drilling and Production Practices (1941) 200–213.

Perraton, D., Aïtcin, P.-C. et Carles-Gibergues, A., ‘Mesure de la perméabilité aux gaz des bétons: perméabilité apparente et perméabilité intrinsèque. Partie I—Validation des concepts de Carman et de Klinkenberg dans le cas d'un BHP’,LCPC Bulletin (in French)221 (4241) (1999) 69–78.

Bentz, D. P., Snyder, K. A. and Stutzman, P. E., ‘Hydration of portland cement: the effect of curing conditions’, Proceedings of the 10th International Congress on the Chemistry of cement, H. Justnes Ed., Vol. 2, Gothenburg, Sweden (1997).

Rostasy, F. S., Weib, R. and Wiedemann, G., ‘Changes of pores structure of cement mortars due to temperature’,Cem. Concr. Res. 10 (1980) 157–164.

Chan, Y. N., Luo, X. and Sun, W., ‘Compressive strength and pore structure of high-performance concrete after exposure to high temperature up to 800°C’,Cem Concr. Res. 30 (2) (2000) 247–251.

Piasta, J., Sawicz, Z. and Rudzinski, L., ‘Changes in the structure of hardened cement paste due to high temperature’,Mater. Struct. 100 (1984) 291–296.

Ulm, F.-J., Acker, P. and Levy, M., ‘The chunnel fire. I: chemosplatic softening in rapidly heated concrete’,ASCE J. Eng. Mech. 125 (3) (1999) 272–282.

Harmathy, T. Z., ‘Thermal properties of concrete at elevated temperatures’,ASTM J of Mat. 5 (1) (1970) 47–44.

Sercombe, J., Gallé, C., Durand, S. and Bouniol, P., ‘On the importance of thermal gradients in the spalling of high-strength concrete’, 14th Engineering Mechanics Conference ASCE, Austin, Texas, USA, 21–24 May, 2000.

Le Roy, R., ‘Déformations instantanées et différées des bétons à hautes performances’, Research Report from the Laboratoire Central des Ponts et Chaussées (in French), N° OA22, Paris, 1996.

Author information

Authors and Affiliations

Additional information

Editorial Note CEA (Saclay) is a RILEM Titular Member.

Rights and permissions

About this article

Cite this article

Gallé, C., Sercombe, J. Permeability and pore structure evolution of silicocalcareous and hematite high-strength concretes submitted to high temperatures. Mat. Struct. 34, 619–628 (2001). https://doi.org/10.1007/BF02482129

Received:

Accepted:

Issue Date:

DOI: https://doi.org/10.1007/BF02482129