Abstract

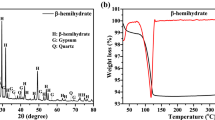

Gypsum produced by flue-gas desulfurization (FGD gypsum) from the Mae Moh power plant, Thailand, was precleaned, characterized and used as the starting material for the preparations of β-hemihydrate (β-HH) and multiphase plasters with compositions within the three-phase composition diagram of calcined gypsum [1]. Based on performance requirements of commercial products, the plasters obtained were fabricated into gypsum board specimens using various additives as set regulators. The effect of the additives on the morphology and mechanical properties of the set plasters was studied in comparison with those from natural gypsum. With the exception of calcium sulfate dihydrate, it was found that additives caused a characteristic change in structure with a trend towards reduction of the aspect ratio of the hydrate crystals, as well as a decrease in strength. The set plasters obtained from FGD gypsum had higher strengths due to the finer crystal size of the hydrate.

Résumé

On a fait subir à du gypse de désulfurisation (FGD), issu de la centrale thermique de Mae Moh, en Thaïlande, un traitement initial de nettoyage, avant de le caractériser du point de vue chimique et physique, et de l'utiliser comme produit de départ dans la préparation de semihydrate béta (β-HH) et de plâtres multiphases dont la composition se situe à l'intérieur du diagramme triphasique du gypse calciné [1]. En se basant sur le cahier des charges de produits commerciaux existants, les plâtres obtenus ont servi à fabriquer des échantillons de plaques de plâtre en utilisant différents additifs et mofificateurs de prise. L'effet des additifs sur la morphologie et les propriétés mécaniques des plâtres pris a été etudié et comparé aux effets sur des gypses naturels. À l'exception du sulfate de calcium bihydraté, il a été montré que les additifs étudiés provoquent des changements caractéristiques de structure avec une tendance à la réduction du facteur d'aspect des cristaux hydratés, en même temps qu'une diminution de la résistance. Les plâtres pris obtenus à partir de FGD ont des résistances mécaniques supérieures du fait de la taille plus fine des cristaux de plâtre hydraté.

Similar content being viewed by others

References

Wirsching, F., ‘Calcium sulfate’, ‘Ullman's Encyclopedia of Industrial Chemistry’, (Brothers Knauf West Germany Gypsum factories Iphofen, Germany, 1985).

Koslowki, T. and Ludwig, U., ‘Retardation of gypsum plasters with citric acid: mechanism and properties’, in ‘The Chemistry and Technology of Gypsum’, Symposium of Gypsum and Related Building Materials and Systems, Atlanta, GA, April 1983 (ASTM STP 861, 1984) 97–104.

Lach, V., ‘Microstructure of hydrated moulding plaster’,Interceram (3) (1985) 31–34.

Bosbach, D. and Hochella Jr. M. F., ‘Gypsum growth in the presence of growth inhibitors: a scanning force microscopy study’,Chemical Geology (132) (1996) 227–236.

Hubert, C. F., ‘Gypsum, the silent partner’,Ceram. Eng. Sci. Proc. 15 (1) (1994) 34–38.

Kuhlmann, J. and Ludwig, U., ‘Soundness of building gypsum’,Zem. Kalk. Gips.,30 (5) (1977) 214–218.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Prakaypun, W., Jinawath, S. Comparative effect of additives on the mechanical properties of plasters made from flue-gas desulfurized and natural gypsums. Mat. Struct. 36, 51–58 (2003). https://doi.org/10.1007/BF02481571

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/BF02481571