Abstract

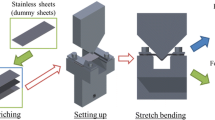

Thermoplastic composites with continuous fibres are attractive construction materials because of their good specific mechanical properties and their possibility to be processed very rapidly. An extremely fast processing method is folding of sheet material. Folding can be performed by local heating of a sheet along a line. Heating is done to a temperature, well above the softening or melting point of the thermoplastic polymer. Subsequent folding along the heated line requires very low forces. The folded geometry becomes permanent after cooling below the softening point of the polymer. Unfortunately, folding causes microbuckling of the reinforcing fibres at the compression side of the fold causing a severe reduction in the local strength. The present report describes a method for the folding of thermoplastic composites, which controls the direction of fibre microbuckling. The method results in a smaller strength reduction.

The folding equipment is designed in such a way that microbuckling of the fibres occurs in a direction in the local plane of the sheet rather than being perpendicular to that plane. The result is a folded sheet with a reduction of about half of the original strength, as compared to a strength of only 15% of the original strength, which is typical for folds produced with more conventional means. In other words, the remaining strength is more then doubled using the new folding technology.

Similar content being viewed by others

References

Marissen, R., Hornman, H. H. H., Wenmakers, L. E. P. and Scholle, K. F. M. G. J., ‘Advanced Thermoplastic Composites for Low Cost Structural Applications’, inProceedings of the SAMPE 11th Int. European Chapter Conference, Basel, Switzerland, May 29–31, 1990, pp. 41–56.

Marissen, R., Hornman, H. H. H., Wenmakers, L. E. P., Robroek, L. M. J. and Brouwer, W. D., ‘Thermoplastic Composites with a High Content of Continuous Aligned Fibres for Automotive Applications’, inProceedings of the ASM/ESD Conference, Dearborn, Michigan, U.S.A., Sept. 30–Oct. 3, 1991, pp. 331–337.

Robroek, L. M. J., ‘The Development of Rubber Forming as a Rapid Thermoforming Technique for Continuous Fibre Reinforced Thermoplastic Composites’, PhD thesis work, Delft University of Technology, 1994.

van de Grampel, H. T., ‘New Developments and Applications in Thermoplastic Composites’, inProceedings of Verbundwerk '91 Conference, Wiesbaden, Germany, Oct. 9–11, 1991, pp. M4.1–M4.15.

Eckenberger, J., Effing, M., Staub, B. and Walrave, A.: ‘TEPEX, The Revolution in Mass-Production of Advanced Composites’, inProceedings of the 4th Japan International SAMPE Symposium, Sep. 25–28, 1995.

Marissen, R., Hornman, H. H. H., Wenmakers, L. E. P., Robroek, L. M. J. and Brouwer, W. D., ‘Processing of Continuous Fibre Reinforced Thermoplastic Composites for Multi-Purpose Engineering’, inProceedings of Verbundwerk '91 Conference, Wiesbaden, Germany, Oct. 9–11, 1991, pp. M5.1–M5.14.

van Dreumel, W. H. M., ‘Origami-Technology, Creative Manufacturing of Advanced Composites Parts’,Composites Polymers, an International Journal 3(1), 1990, ISBN 0952-6919.

‘ASTM D790M-82’, Standard Test Methods for Flexural Properties of Unreinforced and Reinforced Plastics and Electrical Insulating Materials.

Kedward, K. T., Wilson, R. S. and Mc Lean, S. K., ‘Flexure of Simply Curved Composites Shapes’,Composites 20(6), Nov. 1989, 527–536.

Lekhnitskii, S. G.,Anisotropic Plates, Gordon and Breach Science Publishers, USA, 1968.

Hiel, C. C., Sumich, M. and Chappell, D. P., ‘A Curved Beam Test Specimen for Determining the Interlaminar Tensile Strength of a Laminated Composite’,Journal of Composite Materials 25, July 1991, 854–868.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Marissen, R., Van Der Drift, L.T. & Sterk, J.C. Folding of continuous fibre thermoplastic composites. Appl Compos Mater 4, 273–282 (1997). https://doi.org/10.1007/BF02481394

Received:

Accepted:

Issue Date:

DOI: https://doi.org/10.1007/BF02481394