Abstract

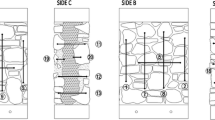

The punching shear capacity of a wood-based panel is useful in the assessment of its suitability in flooring. A test method for determination of the punching shear capacity of particleboard is given in British Standard BS 5669. The suitability of the span of test piece specified in BS 5669 for punching shear capacity characterisation of oriented strand board (OSB) has been assessed from concentrated load tests of 15 and 18-mm thick OSB panels under 25 and 50-mm diameter load applicators. Elliptical fan-shaped crack envelopes with major axes that were roughly of the same order as the spans of the test pieces characterised the failure of the test pieces under the 25-mm diameter load applicator. However, when the test pieces were loaded via the 50-mm diameter load applicator, the spans of the test pieces appeared too small to simulate the characteristic elliptical crack envelope. An expression for the test-piece span for characterisation of punching shear capacities under both 25 and 50-mm diameter load applicators has been proposed. The proposed expression is a useful starting point in the determination of suitable test-piece span for punching shear capacity characterisation of OSB.

Résumé

La capacité de cisaillement par perforation d’un panneau à base de bois est utile pour évaluer l’appropriation de son choix dans les planchers. La norme britannique BS 5669 propose une méthode visant à déterminer la capacité de cisaillement par perforation de panneaux de particules. La conformité de la dimension du spécimen mentionnée dans la norme BS 5669 sur la caractérisation de la capacité de cisaillement par perforation de panneaux de copeaux orientés (OSB) a été évaluée à partir d’essais en charge concentrée de panneaux de copeaux orientés de 15 et 18 mm d’épaisseur sous des applicateurs de charges de 25 et 50 mm de diamètre. Des enveloppes de fissuration en forme d’éventails elliptiques, dont les axes principaux avaient à peu près la même taille que la portée des spécimens, ont montré la rupture des spécimens sous un applicateur de charge d’un diamètre de 25 mm. Cependant, lorsque les spécimens ont été chargés par l’applicateur de 50 mm de diamètre, la portée des spécimens s’est révélée trop petite pour simuler l’enveloppe de fissuration elliptique caractéristique. La portée des spécimens pour la caractérisation de la capacité de cisaillement par perforation sous des applicateurs de charges de 25 et 50 mm de diamètre a été proposée. Il s’agit d’un point de départ utile dans la détermination de la portée la mieux adaptée pour la caractérisation de la capacité de cisaillement par perforation de panneaux de copeaux orientés.

Similar content being viewed by others

References

Soothill, C., ‘Punching shear strength of wood chipboard—Part 1: Initial assessment of the influence of board thickness, punch size, joist spacing and tongue-and-groove joints on the resistance of chipboard to gradually applied concentrated loads’, Research report 5/83, Timber Research and Development Association, High Wycombe, Bucks., England (1983).

British Standards Institution, ‘BS 5669 Particleboard—Part 1, 1989—Methods of sampling, conditioning and test’, British Standards Institution, London, England (1989).

Griffiths, D. R. and Wickens, H. G., ‘CEC Programme: Design Stresses for OSB. University of Surrey tests and reduction of results’, Department of Civil Engineering, University of Surrey, Guildford, Surrey, England (1995).

Timoshenko, S. P. and Woinowsky-Krieger, S. ‘Theory of plates and shells’, 2nd Edn. (McGraw-Hill Inc., New York, USA, 1959).

Donnell, L. H., ‘Beams plates and shells’, (McGraw-Hill Inc., New York, USA, 1976).

Park, R. and Gamble, W. L., ‘Reinforced concrete slabs’, (John Wiley and Sons Inc., New York, USA, 1980).

European Committee for Standardisation, ‘EN 789:1992 Timber structures—Testing of wood panels for the determination of mechanical properties for structural purposes’, European Committee for Standardisation, Brussels, Belgium (1992).

Thomas, W. H., ‘Bending behaviour of OSB decking under concentrated load’, PhD thesis, University of Surrey, Guildford, Surrey, UK (1996).

Shrestha, D., ‘Shear properties tests of oriented strandboard panels’,Forest Products Journal 49 (10) (1999) 41–46.

Karacabeyli, E., Lau, P., Henderson, C. R., Meakes, F. V. and Deacon, W., ‘Design rated oriented strandboard in CSA standards’,Canadian Journal of Civil Engineering 23 (1996) 431–443.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Thomas, W.H. Assessment of test-piece size for punching shear capacity of orthotropic panels: Case study of OSB. Mat. Struct. 36, 139–144 (2003). https://doi.org/10.1007/BF02479528

Received:

Accepted:

Issue Date:

DOI: https://doi.org/10.1007/BF02479528