Abstract

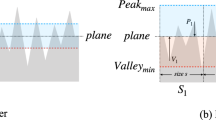

The microrelief that forms as a result of sectioning and polishing of a sample of concrete can be studied with optical techniques, but it can also be analyzed with surface roughness instruments. Stylus instruments for measuring surface roughness use the principle of the well-known pick-up element. A needle with a very fine diamond at its tip is driven at constant speed over the microrelief to be measured. The vertical movements of the needle are converted into changes in electrical current by the pick-up element. The speed of the motor-drive of the stylus determines the horizontal enlargement factor in combination with the speed of the paper chart recorder. Electronic amplification of the signal obtained makes possible vertical enlargement factors of up to 100,000 times. Calibration of this type of equipment can take place by measuring the well-defined topography of calibration blocks, but calibration based on optical measurement is also possible. Samples of concrete have to be cut by a thin diamond wheel, polished on silicon carbide paper, and etched in dilute acetic acid. Quantification of the measurements made in linear analysis typical of surface roughness equipment is based on the recognition of two of the components of concrete: air bubbles and aggregate. Air bubbles form deep, steep-walled depressions in the recorded signal. Aggregate can be recognized by its forming distinctly flat-topped hillocks. An example of the measurement technique involved is given.

Résumé

Il est possible d'analyser le microrelief qui se forme après avoir scié et poli un échantillon de béton par des méthodes optiques, mais il est aussi possible de l'analyser avec la technique de l'inégalité de surface. Les instruments qu'on utilise pour ces mesures reposent sur le principe du pick up. L'aiguille de cet instrument qui s'ajuste à un très petit diamant est mise en mouvement constant à travers le microrelief. Les mouvements verticaux de l'aiguille sont convertis en signaux électriques. La vitesse d'entraînement détermine, en combinaison avec la vitesse de déroulement du papier enregistreur le facteur d'agrandissement horizontal. Un agrandissement jusqu'à 100 000 dans le sens vertical est possible grâce à l'amplification électronique du signal. Les échantillons en béton doivent être coupés avec une scie à diamant très mince, polis au papier à carbure de silicium, et attaqués à l'acide acétique dilué. L'évaluation des mesures linéaires auxquelles on procède par cette méthode est possible après avoir rendu compte des deux composants du béton: bulles d'air et granulats. Les bulles d'air se traduisent par des descentes abruptes du signal enregistré, et les granulats par des crêtes aplaties. On donne un exemple de la technique de mesure.

Similar content being viewed by others

References

Abbott E. J., Firestone F. A.—Specifying surface quality (A method based on accurate measurement and comparison). Mechanical Engineering, Vol. 55, 1933, pp. 569–572.

Adams F. W., Devol L., Letner H. R.—An instrument for studying the topographies of fine textured surfaces, Rev. Sc. Instrum. (Lancaster, U.S.A.), Vol. 12, 1941, A, pp. 409–411.

Adams F. W., Devol L., Letner H. R.—An instrument for studying fine texture of ceramic and other surfaces. Journ. Am. Ceram. Soc., Vol. 24, 1941, B, pp. 229–234.

Alliet D. F., Tietjen T. A., Wood D. H.—Particle size analysis of multicomponent toner systems, 1978, pp. 31–43,in:Groves M. J. ed.: Particle size analysis, Heyden, London, 492 p.

Barwell F. T.—Tribological implications of surfaces. Proc. Inst. Mech. Engrs. (London), Vol. 182, 1968, pp. 1–20.

Blümel O. W.—Ein Folien-Abdruckverfahren zur besseren Sichtbarmachung von Poren im Beton. Radex Rundschau, Jg. 1967, pp. 466–471.

Brown L. S., Pierson C. U.—Linear traverse technique for measurement of air in hardened concrete. Proc. Am. Concrete Inst., Vol. 47, 1950, pp. 117–123.

Chatterji S, Gudmundson H.—Characterization of entrained air bubble systems in concretes by means of an image analyzing microscope. Cem. & Concr. Research, Vol. 7, 1977, pp. 423–428.

Consley D., Young J. Z.—Counting and sizing of particles with the flying spot microscope. Nature, Vol. 176, 1955, pp. 453–454.

Deelman J. C.—Automatic grain size analysis by means of electro-magnetic surface measurements. Jour. Sed. Petrol., Vol. 42, 1972, pp. 732–735.

Deelman J. C., Deelman G. J.—Textural analysis of sediments by means of surface roughness measurements. Neues Jahrbuch f. Geol. u. Pal., Mh., Jg. 1975, pp. 65–81.

Dell H. A., Hobbs D. S., Richards M. S.—Ein Gerät zur Zahlung mikroskopischer Teilchen und zur Bestimmung ihrer Grössenverteilung, Philips Techn. Rundschau, Vol. 22, 1960, pp. 1–36.

Ireland H. A.—Preparation of thin-sections, pp. 367–383,in:Carver R. E. ed.: Procedures in sedimentary petrology, Wiley-Interscience, New York, 1971, 653 p.

Kleine-Büning H., Scheer O.—Herstellung von Dünnschliffen für die automatische Bildanalyse von Betonproben. Betonwerk & Fertigteil Technik, Jg. 1980, pp. 240–245.

Loeb H. W.—Flying spot counting and sizing of nonuniform particles. Brit. Jour. Applied Physics, Vol. 7, 1956, pp. 440–441.

Morton R. A., Martens A. E.—Electronic image measurement. Research Developments, Vol. 23, 1972, pp. 24–28.

Perthen J.—Testing and measuring surface features. Hanser Verlag, München, 1949, 257 p.

Powers T. C.—The properties of fresh concrete. Wiley & Sons, New York, 1968, 664 p.

Redman E., Heckman F. A., Connolly J. E.—A practical approach to reliable quantitative image analysis of carbon black electron micrographs, 1978, pp. 51–60,in:Groves M. J. ed.: Particle size analysis, Heyden, London, 492 p.

Richards P. J.—Review of methods of measurement of surface and assessment of surface form and texture. Proc. Inst. Mech. Engrs. (London), Vol. 182, 1968, pp. 453–465.

Romer B., Dobrolubov G.—Angewandte Mikroskopie bei der Baustoffprüfung-Beton, Mörtel, Zement, Kalk, Gips, Keramik. Leitz Mitteilungen, Vol. 6, 1974, pp. 135–144.

Saiffoulline R. S.—Matériaux métalliques poreux réalisés par l'électrodéposition de la suspension, 1974, pp. BB59–66,in:Modrý S. andSvatá M. eds.:Pore structure and properties of materials, Proc. Int. Symp., Prague, 1973, Final Report, Academia, Prague, 244 p.

Schlesinger G.—Messung der Oberflächengüte. Springer-Verlag, Berlin, 1951, 248 p.

Schluge H.—Ein neues Teilchengrösse-Messgerät. Z. f. Aerosol Forschung u. Therapie, Vol. 4, 1955, pp. 513–516.

Sharman H. B.—Calibration of surface texture measuring instruments. Proc. Inst. Mech. Engrs. (London), Vol. 182 (Pt. 3 K), 1968, pp. 319–326.

Spragg R. C.—Accurate calibration of surface texture and roundness measuring instruments. Proc. Inst. Mech. Engrs. (London), Vol. 182 (Pt. 3 K), 1968, pp. 397–405.

Taylor W. K.—An automatic system for obtaining particle size distributions with the aid of flying-spot microscope. Brit. Jour. Applied Physics, Vol. 5 (Suppl. No. 3), 1954, pp. 173–175.

Textoris D. A.—Grain-size measurement in thin-section, 1971, pp. 95–107,in:Carver R. E. ed.: Procedures in sedimentary petrology, Wiley-Interscience, New York, 653 p.

Timms C.—Measurement of surface roughness. Metal Treatment, Vol. 13, 1946, pp. 111–118.

Trumpold H.—Limits of application of the interference methods for surface measurements. Proc. Inst. Mech. Engrs. (London), Vol. 182 (Pt. 3 K), 1968, pp. 241–254.

Underwood E. E.—Quantitative stereology. Addison-Wesley, Reading (Mass.), 1970, 274 p.

Walz K., Helms-Derfert H.—Luftporen-Kennwerte von Betonfahrdecken-Einfluss auf das Abwittern durch Tausalze. Betontechn. Berichte, Jg. 1966, pp. 75–87.

Wolff H.—Surface testing using the Hommel Tester Type T. Proc. Inst. Mech. Engrs. (London), Vol. 182 (Pt. 3 K), 1968, pp. 279–298.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Deelman, J.C. Textural analysis of concrete by means of surface roughness measurements. Mat. Constr. 17, 359–367 (1984). https://doi.org/10.1007/BF02478708

Issue Date:

DOI: https://doi.org/10.1007/BF02478708