Conclusions

-

1.

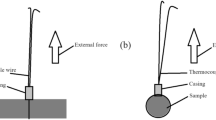

The freezing-on of babbitt onto a plane surface is an effective fective means for the production and repair of plane bearings.

-

2.

The thickness of the freezed-on babbitt layer is directly proportional to the degree of the supercooling and the hold time of the bearing in the liquid melt.

-

3.

The freezed-on babbitt layer does not contain pores, pits, or nonmetallic inclusions.

-

4.

A strong diffusion coupling is formed between the babbitt layer and the specimen.

Similar content being viewed by others

Author information

Authors and Affiliations

Additional information

Translated from Metallovedenie i Termicheskaya Obrabotka Metallov, No. 7, pp. 36–37, July, 1998.

Rights and permissions

About this article

Cite this article

Gromyko, A.G. Formation of shape and structure in freezing-on A babbitt layer. Met Sci Heat Treat 40, 299–300 (1998). https://doi.org/10.1007/BF02474897

Issue Date:

DOI: https://doi.org/10.1007/BF02474897