Conclusions

-

1.

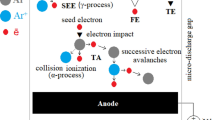

The maximum density of plasma energy, the qualitative characteristic of which is the specific power of the discharge, provides the greatest thickness of the diffusion layer in saturation from a gas medium at a constant temperature.

-

2.

The dependence of the specific power of the discharge on the pressure of the saturating medium has a maximum in various kinds of ITCT of metals and alloys, i.e., nitriding, carburizing (nitrocarburizing), and siliconizing.

-

3.

The energy characteristic of the glow discharge, i.e., its specific power, should be one of the main factors determining the diffusion saturation in all kinds of ITCT.

Similar content being viewed by others

References

B. N. Arzamasov,Thermochemical Treatment in Activated Gas Media [in Russian], Mashinostroenie, Moscow (1979).

B. Edenhofer, “Fortshritte in prozeβregelung beim Plasmanitrieren,”Harten-Technische Mitteilung,44(6), 339–345 (1989).

A. E. Mezhonov and V. E. Kol'tsov, “A thermodynamic model of the process of nitriding in glow discharge,” in:Methods of Surface Hardening of Machine Parts and Tools, Trudy MADI [in Russian], Moscow (1983), pp. 53–59.

T. A. Panaioti, “Effect of pressure in gas-discharge chamber on the depth of nitrogen diffusion in titanium alloys,”Metalloved. Term. Obrab. Met., No. 9, 32–35 (1998).

A. A. Babad-Zakhryapin and G. D. Kuznetsov,Thermochemical Treatment in Glow Discharge [in Russian], Atomizdat, Moscow (1975).

N. A. Kaptsov,Electronics [in Russian], Gostekhteorizdat, Moscow (1953).

K. Keller, “Schichtaufbau glimmnitrierten Eisenwerkstoffe,”Harterei Technische Mitteilung,26(2), 120–128 (1971).

B. Edenhofer, “Möglichkeiten und Grenzen der Plasmaaufkohlung: Vorgetragen auf dem 45,” Harterei-Kolloguium (4–6 Oktober 1990, Wiesbaden),Harterei-Technische Mitteilungen,45(3), 154–162 (1990).

B. Edenhofer, “Progress in the control of plasmanitriding and carburizing for better layer consistency and reproducibility,” in:Plasma Surface Engineering: Pap. 1st Int. Conf. Garmisch-Partenkirchen, Sept. 19–23, 1988, Vol. 1, Oberursel (1989), pp. 257–268.

B. N. Arzamasov, A. G. Bratukhin, Yu. S. Eliseev, and T. A. Panaioti,Ion Thermochemical Treatment of Alloys [in Russian], Izd. MGTU im. N. É. Baumana, Moscow (1999).

Author information

Authors and Affiliations

Additional information

Translated from Metallovedenie i Termicheskaya Obrabotka metallov, No. 6, pp. 31–34, June, 2000.

Rights and permissions

About this article

Cite this article

Arzamasov, B.N., Panaioti, T.A. Role of the specific power of discharge in ion thermochemical treatment of alloys. Met Sci Heat Treat 42, 234–237 (2000). https://doi.org/10.1007/BF02471318

Issue Date:

DOI: https://doi.org/10.1007/BF02471318