Abstract

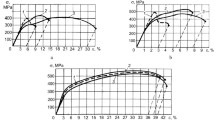

At the present time critical parts of various machines and equipment operating under conditions of wear under cyclic loads are often produced from low-alloy steel 38Kh2MYuA. Its operating properties are usually improved by surface strengthening by the method of nitriding. A wide range of nitrogen-saturating atmospheres has been developed for this purpose, with each diffusion medium characterized by special process properties. The present paper is an analysis of data on nitriding structural steel 38Kh2MYuA in gas, liquid, ionic, vacuum, and powder nitrogen-bearing media. Recommendations are given for practical use of nitriding of the studied steel so as to obtain the requisite operating properties.

Similar content being viewed by others

References

Yu. M. Lakhtin and V. P. Leont'eva,Materials Science [in Russian], Mashinostroenie, Moscow (1990).

V. I. Soldatov, A. E. Mezhonov, V. A. Aleksandrov, and S. I. Bibikov, “Development of the process and equipment for nitriding steels in an atmosphere of ammonia and air,”Metalloved. Term. Obrab. Met., No. 12, 28–30 (1988).

Yu. M. Lakhtin, “Surface strengthening of steels and alloys,”Metalloved. Term. Obrab. Met., No. 11, 14–25 (1988).

Yu. M. Lakhtin, “High-temperature nitriding,”Metalloved. Term. Obrab. Met., No. 2, 25–29 (1991).

Metallurgiya, Referat. Zhurnal, No. 10, 135 (1991).

S. P. Bibikov and G. A. Chaichuk, “The trend in the development of nitriding processes,”Metalloved. Term. Obrab. Met., No. 6, 15–16 (1988).

V. A. Tel'dekov and A. G. Goncharov, “Nitriding intensity in parts from steel 38Kh2MYuA,”Metalloved. Term. Obrab. Met., No. 5, 19–21 (1990).

N. L. Anichkina, V. S. Bogolyubov, Bogolyubov, V. V. Boiko, et al., “Comparison of the methods of gas, ion, and vacuum nitriding,”Metalloved. Term. Obrab. Met., No. 3, 9–12 (1989).

Fan Dun-Li, “Ion chemical heat treatment in the Korean People's Republic,”Metalloved. Term. Obrab. Met., No. 6, 17–19 (1992).

Metallurgiya, Referat. Zhurnal, No. 7, 94 (1991).

Yu. M. Lakhtin, Ya. D. Kogan, and S. M. Soshkin, “Vacuum nitriding of steels,”Metalloved. Term. Obrab. Met., No. 9, 13–15 (1980).

N. N. Varygin and E. Ya. Ol'shanov, “Use of a fluidized bed for heat treatment and surface impregnation of metals,”Metalloved. Term. Obrab. Met., No. 6, 2–11 (1971).

A. S. Zavarov and S. V. Grachev, “Heat treatment and surface impregnation in a fluidized bed,”Metalloved. Term. Obrab. Met., No. 10, 36–38 (1987).

Metallurgiya, Ref. Zh., No. 8, 114 (1985).

Author information

Authors and Affiliations

Additional information

Translated from Metallovedenie i Termicheskaya Obrabotka Metallov, No. 11, pp. 19–21, November, 1997.

Rights and permissions

About this article

Cite this article

Savintsev, M.I. Strengthening steel 38Kh2MYuA by nitriding in various media. Met Sci Heat Treat 39, 471–473 (1997). https://doi.org/10.1007/BF02469114

Issue Date:

DOI: https://doi.org/10.1007/BF02469114