Conclusions

-

1.

We have managed to fabricate a part with a high geometrical precision of passages after creating a unique experimental model.

-

2.

For the first time in the production of turbine wheels we have designed components without using the paper technology, using as a basis

-

-

computer processing of the specified geometry of the flow part and its representation as a system of virtual surfaces;

-

-

three-dimensional simulation of the variation of the capsule shape in HIP and generation of a data file for plotting the surfaces of net shape components;

-

-

processing of the data in a computer-aided design system followed by three-dimensional breadboarding of the net shape components;

-

-

development of control software and data files for the production of net shape components in multi-coordinate N/C machines.

-

3.

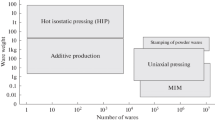

Powder metallurgy based on the HIP process makes it possible to widen the traditional framework of the production of parts with a complex configuration. The HIP process of such parts complemented with advanced concepts and methods of computer simulation and material science is indeed an effective means for creating superduty units and components from promising hard-to-shape materials.

Similar content being viewed by others

References

A. M. Laptev, V. N. Samarov, and S. V. Podlesnyi, “Parameters of hot isostatic pressing of porous materials,”Izv. Akad. Nauk SSSR, Metals, No. 2 (1989).

Khazami Zaden, “Finite simulation of near net shape parts produced by hot isostatic pressing,”Ibid. Izv. Akad. Nauk SSSR, Metals, No. 2 (1989).

D. Seliverstov and V. Samarov, “HIP modeling of complex shape parts: Experience, trends and perspectives.”Ibid. Izv. Akad. Nauk SSSR, Metals, No. 2 (1989).

G. Raisson and V. Samarov, “Design of rules for net shape or near net shape components produced by hot isostatic pressing of superalloy powders,” in:Proc. Powder Metallurgy World Congress (1994).

Additional information

Translated from Metallovedenie i Termicheskaya Obrabotka Metallov, No. 10, pp. 34–36, October, 1999.

Rights and permissions

About this article

Cite this article

Seliverstov, D.G., Samarov, V.N., Kratt, E.P. et al. A new technology for fabricating parts with a complex configuration from powder high-temperature nickel alloys. Met Sci Heat Treat 41, 457–459 (1999). https://doi.org/10.1007/BF02469099

Issue Date:

DOI: https://doi.org/10.1007/BF02469099