Conclusions

-

1.

The mechanical properties, the microstructure, and the phase composition of steel 07Kh16N6 with different contents of carbon after a heat treatment simulating the production process of a part from steel 07Kh16N6 and granulated nickel alloy ÉP741NP joined by the method of HIP fully recover the optimum values after the final heat treatment by a regime recommended for steel 07Kh16N6. The mechanical properties of alloy ÉP741NP do not worsen.

-

2.

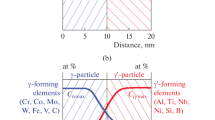

Counter diffusion of Fe, Cr, and C from the steel into the alloy and of Ti, Al, Nb, W, and Mo from the alloy into the steel is observed in the diffusion zone of the combined preform. A narrow (15–20 μm) carbide zone with an elevated concentration of titanium is formed due to the counter diffusion over granule boundaries of alloy ÉP741NP. The depth of iron diffusion into alloy ÉP741NP is 40–50 μm.

-

3.

The mechanical properties of the combined preform at a temperature ranging from −196 to +650°C are close to the properties of steel 07Kh16N6; fracture occurs predominantly over the diffusion zone.

-

4.

In order to raise the working capacity and reliability of units with rotating parts from alloy ÉP741NP joined permanently to a shaft from steel 07Kh16N6 by the method of HIP, the shaft should be coated with a nickel barrier layer that diminishes the possibility of the formation of titanium carbide on the surface of alloy ÉP741NP over granule boundaries.

Similar content being viewed by others

References

G. H. Hessinger,Powder Metallurgy of High-Temperature Alloys [Russian translation], Metallurgiya, Chelyabinsk (1988).

I. Scams and V. Hagel,High-Temperature Alloys [Russian translation], Metallurgiya, Moscow (1976).

E. N. Rudnitskii, O. Kh. Fatkullin, V. I. Eremenko, et al., “Physical metallurgy aspects of the creation of combined parts from high-temperature nickel alloys,”Metalloved. Term. Obrab. Met., No. 12, 18–20 (1991).

Additional information

Translated from Metallovedenie i Termicheskaya Obrabotka Metallov, No. 10, pp. 25–29, October, 1999.

Rights and permissions

About this article

Cite this article

Derkach, G.G., Zheleznyak, O.N., Pestov, Y.A. et al. A study of the diffusion zone in steel 07Kh16N6 and granulated nickel alloy ÉP741NP formed in the process of hot isostatic pressing. Met Sci Heat Treat 41, 446–450 (1999). https://doi.org/10.1007/BF02469096

Issue Date:

DOI: https://doi.org/10.1007/BF02469096