Abstract

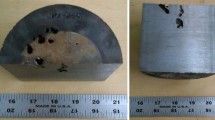

High-alloyed high-temperature nickel-base alloy ZhS32-VI is used for manufacturing blades of gas turbine engines by the method of rapid directed crystallization. The alloy contains boron, zirconium, sulfur, phosphorus, and rare-earth elements. Due to the complex composition the dendritic structure of the alloy may contain segregates with a melting temperature below the temperature of its homogenization. The present work concerns the development of a regime for heat treatment of the alloy that would give castings with a dense and uniform structure and high properties.

Similar content being viewed by others

Author information

Authors and Affiliations

Additional information

Translated from Metallovedenie i Termicheskaya Obrabotka Metallov, No. 1, pp. 25–27, January, 1997.

Rights and permissions

About this article

Cite this article

Lysenko, N.A., Klochikhin, V.G., Dolgov, B.V. et al. Regime for homogenizing a high-temperature nickel alloy fabricated by the method of rapid directed crystallization. Met Sci Heat Treat 39, 28–31 (1997). https://doi.org/10.1007/BF02467206

Issue Date:

DOI: https://doi.org/10.1007/BF02467206