Abstract

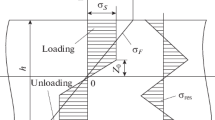

As is known, sheet metal undergoing cold reduction exerts large unit pressures on the rolls. Thus, the total pressures exerted on the rolls by the sheet are also large. With respect to the magnitudes of the stresses (working, mechanical) created in the work rolls during their interaction, with the sheet and the magnitudes of the residual “quenching” and thermal stresses created by nonuniform temperature fields, the rolls operate in a state that is close to the limiting state defined by the given strength criterion. Thus, the problems encountered in attempting to improve the service life of the rolls are closely related to the need for detailed, systematic study of each type of stress individually.

Similar content being viewed by others

References

A. I. Tselikov, G. S. Nikitin, and S. E. Rokotyan,Theory of Longitudinal Rolling [in Russian], Metallurgiya, Moscow (1980).

V. A. Nikolaev, “Length of the contact arc in rolling with allowance for elastic strains of the rolls and the strip”Izv. Vyssh. Uchebn. Zaved. Chern Metall., No. 4, 57–59 (1987).

“Prospects for a five-high mill,”Iron and Steel International,56, No. 5, 164–166 (1983).

V. F. Potapkin, V. A. Fedorinov, I. A. Morozov, and A. V. Satonin, “Calculation of the profile of the roll gap for a stand with one drive roll,”Izv. Vyssh. Uchebn. Zaved. Chern. Metall., No. 1, 57–60 (1986).

A. V. Nogovitsin, Symposium, MChM SSSR (Ministry of Ferrous Metallurg of the USSR). Metallurgiya, Moscow (1988), pp. 58–65.

Ya. D. Vasilev, “Effect of asymmetry of the normal stress distribution on the length of the contact arc between the strip and the roll in cold reduction and temper rolling,”Izv. Vyssh. Uchebn. Zaved. Chern. Metall., No. 3, 49–52 (1985).

M. Ya. Brovman,Shaping of Metals: Symposium. Izd-vo VILS, Moscow (1971), No. 5, 140–152.

A. I. Tselikov and A. I. Grishkov,Theory of Rolling [in Russian], Metallurgiya, Moscow (1970).

I. Ya. Shtaerman,Contact Problems of the Theory of Elasticity [in Russian], Gostekhteorizdat, Moscow-Leningrad (1949).

Additional information

Novokramatorsk Machine Factory. Translated from Metallurg, No. 1, pp. 44–46, January, 1999.

Rights and permissions

About this article

Cite this article

Sevast'yanov, V.S., Belobrov, Y.N. & Tiunov, V.N. Unidimensional mathematical model of the cold reduction of sheet. Metallurgist 43, 35–40 (1999). https://doi.org/10.1007/BF02466980

Issue Date:

DOI: https://doi.org/10.1007/BF02466980