Abstract

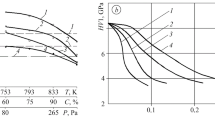

Among all the kinds of surface hardening of titanium alloys ion nitriding in a hydrogen-free medium is the most efficient and environmentally safe. The time of nitrogen saturation of titanium alloys by this method is 10–15 times shorter than in conventional nitriding. The acceleration of the diffusion of nitrogen under conditions of a glow discharge makes it possible to conduct the nitriding of (α+β)-titanium alloys at low temperatures that correspond to those of their aging, which had been impossible earlier. Diffusion saturation in ion surface impregnation is a multifactor process, which makes it controllable. One of the main controlling factors of ion nitriding is the pressure of the working gas. A study of the effect of the pressure in the gas-discharge chamber on the depth of nitrogen diffusion in titanium alloys (under conditions of stable existence of the glow discharge) made it possible to determine the dependence of the thickness of the layer and the specific power of the discharge on the nitrogen pressure and to determine the interrelation between the specific power and the saturating capacity of the gas medium.

Similar content being viewed by others

References

T. D. Panaioti and G. V. Solov'ev, “Ion nitriding of α- and (α+β)-titanium alloys”,Vestnik MGTU, Ser. Mashinostr., No. 1, 15–24 (1994).

T. A. Panaioti and G. V. Solov'ev, “Special features of the formation of diffusion layers in ion nitriding of α- and (α+β)-titanium alloys in the 500–1000°C temperature range”,Metalloved. Term. Obrab. Met., No. 5, 34–37 (1994).

N. I. Martovitskaya, “Determination of the thickness of the nitride layer in nitrided steels”,Metalloved. Term. Obrab. Met., No. 2, 31–36 (1983).

Yu. M. Lakhtin, Ya. D. Kogan, and V. N. Shaposhnikov, “Optimization of gas-dynamic and energy parameters of ion nitriding”,Metalloved. Term. Obrab. Met., No. 6, 2–6 (1976).

Yu. M. Lakhtin, Ya. D. Kogan, and V. N. Shaposhnikov, “A study of the process of nitriding steel in a glow discharge”,Elektr. Obrab. Mater., No. 5, 15–18 (1976).

A. D. Scott and A. B. Belotski, “Influencia de la presion en la profundidat de la capa nitrurada por bombardero ionico en el sistem Fe−Mn−Ti”,Construccion de Maguinaria,7 (1), 31–36 (1982).

D. A. Prokoshkin, T. A. Panaioti, A. P. Sokolov, and S. V. Moskvich, “Effect of the process factors of ion nitriding on the properties of maraging steels”,Izv. Vuzov. Mashinostr., No. 3, 116–119 (1984).

D. A. Prokoshkin, T. A. Panaioti, and G. V. Solov'ev, “A study of ion nitriding of titanium”,Izv. Vuzov. Mashinostr., No. 5, 107–110 (1985).

T. A. Panaioti,Nitriding of High-Strength Steels and Alloys in a Glow Discharge [in Russian], Mashinostroenie, Moscow (1989).

K. Keller, “Schichtaufbau glimmnitrierten Eisen werkstoffe”,Harterei Fechunische Mitteilung,26 (2), 120–128 (1971).

B. Edenhofer, “Progress in the control of plasmanitriding and carburizing for better layer consistency and reproducibility”,Plasma Surf. Eng.,1, 257–268 (1989).

B. Edenhofer, “Fortshritte in der Prozebregegelung beim Plasmanitrieren”,Hartren-Technische Mitteilung,44(6), 339–345 (1989).

B. Edenhofer, “Moglichkeiten und Grensen der Plasmaaufkohlung”,Harefei-Technische Mitteilungen,45 (3), 154–162 (1990).

B. N. Arzamasov,Chemical Heat Treatment in Activated Gas Media [in Russian], Mashinostroenie, Moscow (1979).

I. A. Mikhailov, “Ion proportions in discharge nitriding”,Metalloved. Term. Obrab. Met., No. 10, 50–51 (1965).

B. N. Arzamasov and I. A. Mikhailov, “A study of some processes of ion nitriding”, in:Peredovoi Nauch.-Tekh. i Proizv. Opyt. No. 18-67-1319/113 [in Russian], GOSINTI, Moscow (1967).

I. A. Mikhailov, “A study of channel rays in the glow discharge in nitriding”, in:Protective Coatings on Metals, Issue 1 [in Russian], Naukova Dumka, Kiev (1967), pp. 81–86.

Additional information

Translated from Metallovedenie i Termicheskaya Obrabotka Metallov, No. 9, pp. 32–35, September, 1998.

Rights and permissions

About this article

Cite this article

Panaioti, T.A. Effect of the pressure in the gas-discharge chamber on the depth of nitrogen diffusion in titanium alloys. Met Sci Heat Treat 40, 381–384 (1998). https://doi.org/10.1007/BF02466245

Issue Date:

DOI: https://doi.org/10.1007/BF02466245