Abstract

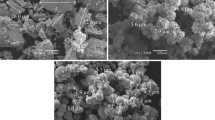

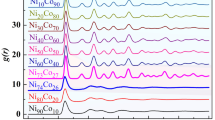

The technological possbilities of directed crystalization are broad and make it possible to manufacture castings from high-temperature alloys with various sets of properties. The present work is devoted to the possibilities of intensifying directed crystallization of the Ni3Al intermetallic compound by improving the system of feeding the growing casting, which makes it possible to control the process of structure formation and thus change the properties of the material.

Similar content being viewed by others

References

A. S. Verin, “Ni3Al intermetallic compound as a base for a high-temperature alloy,”Metalloved. Term. Obrab. Met., No. 5, 26–28 (1997).

A. S. Verin, “Fracture behavior of specimens with single-crystal and directed columnar structures from an alloy based on Ni3Al in a temperature range of 20–1200°C,”Metalloved. Term. Obrab. Met., No. 11, 34–37 (1995).

R. Cahn (ed.),Physical Metallurgy, Amsterdam (1965).

Author information

Authors and Affiliations

Additional information

Translated from Metallovedenie i Termicheskaya Obrabotka Metallov, No. 8, pp. 26–29, August, 1998.

Rights and permissions

About this article

Cite this article

Verin, A.S. Special features of phase formation in Ni3Al intermetallic compound under directed crystallization with dosed feeding of the mother melt to the casting (part 1). Met Sci Heat Treat 40, 332–335 (1998). https://doi.org/10.1007/BF02466221

Issue Date:

DOI: https://doi.org/10.1007/BF02466221