Abstract

Biological hard tissues like bone and shell show combinations of strength and toughness that are hard to duplicate with synthetic materials. These properties are attained by a composite of organic and inorganic phases with very organized microstructures. The structures are hierarchical in that several different scales of organization contribute to the final properties.

Biological systems form by chemical precipitation at room temperature in contrast to synthetic processing, which usually depends on thermal solidification. In principle, chemical solidification can give much more control over composition and structure but is limited by the time taken for diffusion processes in any solid component.

A family of solid freeform fabrication methods have recently been developed which allow parts to be built under the direct control of a 3-dimensional CAD drawing without the need for a mold. These methods also offer a way of building composite structures, with full control of structure and composition at the scale of 100 μm and up. Since this is a layerwise process, like biological growth, diffusion paths are short and so chemical processing of large parts is feasible.

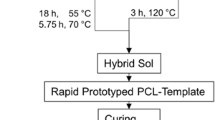

We have been developing an SFF system based on extrusion of a reactive slurry through a 300 μm needle. The needle is moved on three axes so as to build up a part. The application of this method to the formation of components from sol-gel glasses and organic-inorganic hybrids is described.

Similar content being viewed by others

References

C. Viney, Materials Science and Engineering: R10, 187–236 (1993).

S.A. Wainwright, W.D. Biggs, J.D. Currey, and J.M. Gosline,Mechanical Design in Organisms (Princeton University Press, Princeton, NY, 1986).

J.F.V. Vincent,Structural Biomaterials (Princeton University Press, Princeton, 1990).

J.F.V. Vincent, inThe Mechanical Properties of Biological Materials, edited by J.F.V. Vincent and J.D. Currey (Cambridge University Press, Cambridge, 1980), vol. 34, pp. 183–210.

C. Levi, J.L. Barton, C. Guillemet, E. Lebras, and P. Lehuede, J. Materials Science Letters8, 337–339 (1989).

P.B. Kaufman, P. Dayaanandan, Y. Takeoka, W.C. Bigelow, J.D. Jones, and R. Iler, inSilicon and Siliceous Structures in Biological Systems, edited by T.L. Simpson and B.E. Volcani (Springer, Berlin, 1981), pp. 409–450.

R. Garrone, T.L. Simpson, and P. Pottu-Boumendil, inSilicon and Siliceous Structures in Biological Systems, edited by T.L. Simpson and B.E. Volcani (Springer, Berlin, 1981), pp. 495–525.

H.A. Lowenstam and S. Weiner,On Biomineralization (Oxford University Press, Oxford, 1989).

P.A. Dieppe and P.D. Calvert,Crystals and Joint Disease (Chapman and Hall, London, 1983).

J.D. Currey,The Mechanical Adaptions of Bones (Princeton University Press, Princeton, 1984).

C. Sanchez and F. Ribot, New J. Chem.18, 1007–1047 (1994).

J. Burdon and C.P.:Materials Research Society Symposium Proceedings (1993), vol. 286, pp. 315–320.

J. Burdon and P.D. Calvert, inMRS Symposium Hierarchically Structured Materials, edited by I. Aksay, E. Baer, M. Sarikaya, and D.A. Tirrell (Materials Research Society, Pittsburgh, PA, 1992), vol. 255, pp. 375–383.

P.D. Calvert and J.E. Mark, Materials Science and Engineering C1, 159–173 (1994).

B.M. Novak and C. Davies, Macromolecules24, 5481 (1991).

K. Stuffle, A. Mulligan, P. Calvert, and J. Lombardi, Solid freebody forming from polymerizable slurry. Solid Freeform Fabrication Symposium Proceedings. (Univ. of Texas, Austin, 1993), pp. 60–63.

K. Stuffle, A. Mulligan, J. Lombardi, P. Calvert, and B. Fabes, inMater. Res. Soc. Symp. Proc. (1994), vol. 346, pp. 1027–1031.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

O’Kelly, J., Crockett, R., Martin, H. et al. Biomimetic processing of gel glasses and organic-inorganic hybrids. J Sol-Gel Sci Technol 8, 641–644 (1997). https://doi.org/10.1007/BF02436915

Issue Date:

DOI: https://doi.org/10.1007/BF02436915