Abstract

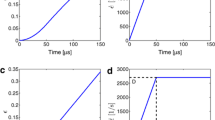

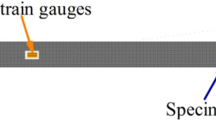

When a conventional split Hopkinson pressure bar (SHPB) is used to investigate the dynamic flow behavior of ductile metals, the results at small strains (ɛ≲2%) are not considered valid owing to fluctuations associated with the early portion of the reflected signal and the nonequilibrated stress state in the specimen. When small-strain behavior is important, such as in the case of determining the elastic behavior of materials, the accuracy of a conventional SHPB is not acceptable. Using a pulse-shaping technique, the dynamic elastic properties can be determined with a SHPB, as well as the dynamic plastic flow. We present a description of the experimental technique and the experimental results for a mild steel. The dynamic compressive stress-strain curve is composed of a lower strain-rate elastic portion and a high strain-rate plastic flow portion.

Similar content being viewed by others

References

Kolsky, H., “An Investigation of the Mechanical Properties of Materials at Very High Rates of Loading,”Proc. R. Soc., B,62,676–700 (1949).

Kolsky, H., Stress Waves in Solids, Dover, New York (1963).

Nicholas, T., “Material Behavior at High Strain Rates,”Impact Dynamics, chap. 8, New York:John Wiley & Sons (1982).

Follansbee, P.S., “The Hopkinson Bar,”Mechanical Testing, Metals Handbook, 9th ed., vol. 8, 198–217.Metals Park, Ohio:American Society for Metals (1985).

Nemat-Nasser, S., Isaacs, J.B., andStarrett, J.E., “Hopkinson Techniques for Dynamic Recovery Experiments,”Proc. R. Soc., A,435,371–391 (1991).

Ramesh, K.T., andNarasimhan, S., “Finite Deformations and the Dynamic Measurement of Radial Strains in Compression Kolsky Bar Experiments,”Int. J. Solids Struct.,33,3723–3738 (1996).

Gray, G.T., “Classic Split-Hopkinson Pressure Bar Technique,”ASM Handbook, vol. 8, Mechanical Testing and Evaluation, ASM International, Materials Park, OH 44073 (2000).

Gray, G.T., andBlumenthal, W.R., “Split-Hopkinson Pressure Bar Testing of Soft Materials,”ASM Handbook, volume 8, Mechanical Testing and Evaluation, ASM International, Materials Park, OH 44073 (2000).

Yadav, S., Chichili, D.R., andRamesh, K.T., “The Mechanical Response of a 6061-T6 Al/Al2O3 Metal Matrix Composite at High Rates of Deformation,”Acta Metall. Mater.,43,4453–4464 (1995).

Wu, X.J., andGorham, D.A., “Stress Equilibrium in the Split Hopkinson Pressure Bar Test,”J. Physique Coll. IV C3 (DYMAT 97),7,91–96 (1997).

Frew, D.J., Forrestal, M.J., andChen, W., “Pulse Shaping Techniques for Testing Brittle Materials with a Split Hopkinson Pressure Bar,” EXPERIMENTAL MECHANICS,42,93–106 (2002).

Frew, D.J., Forrestal, M.J., andChen, W., “A Split Hopkinson Pressure Bar Technique to Determine Compressive Stress-strain Data for Rock Materials,” EXPERIMENTAL MECHANICS,41,40–46 (2001).

Chen, W., andRavichandran, G., “Dynamic Compressive Failure of a Glass Ceramic Under Lateral Confinement,”J. Mech. Phys. Solids,45,1303–1328 (1997).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Chen, W., Song, B., Frew, D.J. et al. Dynamic small strain measurements of a metal specimen with a split Hopkinson pressure bar. Experimental Mechanics 43, 20–23 (2003). https://doi.org/10.1007/BF02410479

Received:

Revised:

Issue Date:

DOI: https://doi.org/10.1007/BF02410479