Abstract

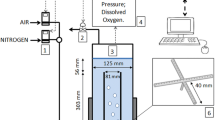

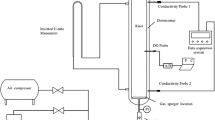

Hydrodynamic and oxygen transfer comparisons were made between two ring sparger locations, draft tube and annulus, in a concentric pilot scale airlift reactor with a baker's yeast suspension. Sectional hydrodynamic measurements were made and a mobile DOT probe was used to characterise the oxygen transfer performance through the individual sections of the reactor.

The hydrodynamic performance of the reactor was improved by using a draft tube ring sparger rather than the annulus ring sparger. This was due to the influence of the ratio of the cross sectional area of the downcomer and riser (A D/AR) in conjunction with the effect of liquid velocity and a parameter,C 0, describing the distribution of the liquid velocity and gas holdup across the riser on the bubble coalescence rates.

The mixing performance of the reactor was dominated by the frequency of the passage of the broth through the end sections of the reactor. An optimum liquid height above the draft tube, for liquid mixing was demonstrated, above which no further improvement in mixing occurred. The liquid velocity and degree of gas entrainment showed little dependency on top section size for both sparger configurations.

Extreme dissolved oxygen heterogeneity was demonstrated around the vessel with both sparger configurations and was shown to be detrimental to the oxygen uptake rate of the baker's yeast. Dissolved oxygen tensions below 1% air saturation occurred along the length of the riser and then rose in the downcomer. The greater oxygen transfer rate in the downcomer than in the riser was caused by the combined effects of a larger slip velocity in the downcomer which enhancedk La and gas residence time, high downcomer gas holdup, and the change in bubble size distribution between the riser and downcomer. The position of greatest oxygen transfer rate in the downcomer was shown to be affected by the reactor from the influence on downcomer liquid linear velocity.

Similar content being viewed by others

Abbreviations

- A D :

-

cross sectional area of the downcomer (m2)

- A R :

-

cross sectional area of the riser (m2)

- C ⋆ :

-

saturation concentration of disolved oxygen (mol. m−3)

- C 0 :

-

distribution parameter, dependent on the radial position of the gas holdup and superficial liquid velocity across the column (-)

- C L :

-

dissolved oxygen concentration (mol. m−3)

- d B :

-

Sauter bubble diameter (m)

- DOT:

-

dissolved oxygen tension (% air saturation)

- H :

-

Henry's law constant for water (Pa. mol fr−1)

- H D :

-

height of the liquid dispersion (m)

- H DT :

-

height of the top of the draft tube from the vessel base (m)

- k L :

-

liquid side mass transfer coefficient (ms−1)

- k La:

-

volumetric mass transfer coefficient (s−1)

- M W :

-

molecular weight of water (kg.m−3)

- N A :

-

rate of oxygen transfer to the liquid phase (mol m−3 liquid. s−1)

- OUR:

-

oxygen uptake rate (mmol.l−1. h−1)

- P :

-

hydrostatic pressure (Pa)

- P IN :

-

pressure at the point of gas inlet to the vessel (Pa)

- Q GO :

-

volumetric flowrate of gas through the sparger (m3. s−1)

- R :

-

universal gas constant (mol. kg−1. s.−1)

- T :

-

absolute temperature (K)

- T EX :

-

absolute temperature of exit gas stream (K)

- T IN :

-

absolute temperature of exit gas stream (K)

- t c :

-

liquid circulation time (s)

- t m :

-

mean mixing time to achieve 90% homogeneity (s)

- V L :

-

liquid volume (m3)

- U LD :

-

mean liquid linear velocity in the downcomer (ms−1)

- U LR :

-

mean liquid linear velocity in the riser (ms−1)

- U sg :

-

superficial gas velocity based on the riser (ms−1)

- x :

-

vertical displacement from the base of the vessel (m)

- y EX :

-

mean oxygen mole fraction of exit gas stream (mol fr)

- y IN :

-

mean oxygen mole fraction of inlet gas stream (mol fr)

- y O2 :

-

oxygen composition of gas (mol fr)

- ρw :

-

density of water (kg·m−3)

- η:

-

solubility in fermentation medium compared with that in water at same conditions (-)

- ε:

-

gas holdup (-)

- εD :

-

means downcomer gas holdup (-)

- ε0 :

-

mean overall gas holdup (-)

- εR :

-

mean riser gas holdup (-)

- εTS :

-

mean top section gas holdup (-)

References

Abel, C.;Hübner, U.;Schügerl, K.: Transient behaviour of Baker's yeast during enforced periodical variation of dissolved oxygen concentration. J. Biotechnol. 32 (1994) 45–57.

Ayazi Shamlou, P.A.;Pllard, D.J.;Ison, A.P.;Lilly, M.D.: Gas holdup and liquid circulation rate in concentric-tube, airlift bioreactors. Chem. Eng. Sci. 49 (1994) 303–312.

Ayazi Shamlou, P.A.;Pollard, D.J.;Ison, A.P.: Volumetric mass transfer coefficient in concentric-tube, airlift bioreactors. Chem. Eng. Sci. 50 (1995) 1579–1590.

Baker, T.W.;Worgan, J.T.: The application of air-lift fermenters to the cultivation of filamentous fungi. Eur. J. Appl. Microbiol. Biotechnol. 13 (1981) 77–83

Bukur, D.B.;Patel, S.A.: Hydrodynamic studies with foaming and non-Newtonian solutions in bubble columns. Can. J. Chem. Engng. 67, (1989) 741–751

Chisti, M.Y.: Airlift Bioreactors. Elsevier Applied Science, U.K., 1989

Chisti, M.Y.;Moo-Young, M.: Hydrodynamic and oxygen transfer in pneumatic bioreactor devices. Biotechnol. Bioeng. 31 (1988) 487–494

Fields, P.R.;Slater, N.K.H.: Tracer dispersion in a laboratory air-lift reactor. Chem. Eng. Sci. 38 (1983) 647–653

Fröhlich, S.;Lotz, M.;Korte, T.;Lubbert, A.;Schügerl, K.;Seekamp, M.: Characterisation of a pilot plant airlift tower loop bioreactor: II Evaluation of global mixing properties of the gas phase during yeast cultivation. Biotechnol. Bioeng. 37 (1991) 910–917

Heijnen, J.J.;van't Reit, K.: Mass transfer, mixing and, heat transfer phemomena in low viscosity bubble column reactors. Chem. Eng. J. 28 (1984) B21–42

Kubota, H.;Hosono, Y.;Fujie, K.: Characteristic evaluations of ICI air-lift type deep shaft aerator. J. Chem. Eng. Japan 11 (1978) 319–325

Lubbert, A.;Fröhlich, S.;Larson, B.;Schügerl, K.: Fluid dynamics in airlift loop bioreactors as measured during real cultivation processes In: King, R (Ed.), Proceedings: 2nd international conference on bioreactor fluid dynamics, pp. 379–393 Elsevier, London, 1988.

McNeil, B.;Kristiansen, B.: Simulated scale-up of a yeast fermentation using a loop bioreactor. Biotechnol. Letts. 12 (1990) 39–44

Merchuk, J.C.;Stein, Y.: Local gas holdup and liquid velocity in airlift reactors. AlChE J., 27 (1981) 377–388

Onken, U;Weiland, P.: Liquid velocity as an important design parameter for airlift loop-fermentors. In: Moo-Young, M., Robinson, C.W., Vezina, C. (Eds.), Advances in biotechnology, vol. 1, pp. 559–564, Pergamon Press, Toronto, Canada, 1981.

Onken, U.;Weiland, P.: Airlift fermenters: construction, behaviour and uses. In: Mizrahi, A., van Wezel, A.L. (eds.). Advances in Biotechnology Processes vol. 1, p 67–95, Liss, A.R. Inc. New York, 1981

Onken, U.;Kiese, S.;Jostmann, Th.: An airlift fermenter for continuous cultures at elevated pressure. Biotech. Letts. 6 (1984) 283–288

Oosterhuis, N.M.G.;Kossen, N.W.F.: Dissolved oxygen concentration profiles in a production scale bioreactor. Biotechnol. Bioeng. 26 (1984) 546–550

Orazem, M.E.;Fan, L.T.;Erickson, L.E.: Bubble flow in the downflow section of an airlift tower. Biotechnol. Bioeng. 21 (1984) 1579–1606

Philip, J.;Proctor, J.M.;Niranjan, K.;Davidson, J.F. Gas hold-up and liquid circulation in internal loop reactors containing highly viscous Newtonian and non-Newtonian liquids. Chem. Eng. Sci. 45 (1990) 651–664

Pollard, D.J.: PhD thesis. University of London, 1995

Russell, A.B.;Thomas, C.R.;Lilly, M.D.: The influence of vessel height and top-section size on the hydrodynamic characteristics of airlift fermentors. Biotechnol. Bioeng. 43 (1994) 69–79

Russell, A.B.;Thomas, C.R.;Lilly, M.D.: Oxygen transfer measurements during yeast fermentations in a pilot scale airlift fermenter. Bioprocess Eng. 12 (1995) 71–79

Schumpe, A.;Quicker, G.;Deckwer, W.D.: Gas solubility in microbial culture media. Adv. Biochem. Eng. 24 (1982) 1–38

Siegel, M.H.;Robinson, C.W.: Applications of airlift gas-liquid-solid reactors in biotechnology. Chem. Eng. Sci. 47 (1992) 3215–3229

Siegel, M.H.;Hallaile, M.;Merchuk, J.C.: Air-lift reactors: design, operation, and applications. In: Mizrahi, A. (ed.) Advances in biotechnological processes, vol. 7, pp. 79–124, Liss, A.R. Inc., New York, U.S.A., 1988

Smith, S.R.L.: Single cell protein. Phil. Trans. Roy. Soc. (London) B.: 290 (1980) 341–354

Sobotka, M.;Prokop A.;Dunn, I.J.;Einsele, A.: Review of methods for measurement of oxygen transfer in microbial systems. Ann. Rep. Ferm. Proc. 5 (1982) 127–210

Sweere, A.P.J.;Janse, L.;Luyben, K.Ch.A.M.;Kossen, N.W.F.: Experimental simulation of oxygen profiles and their influence on baker's yeast production: II. Two-fermenter, system. Biotechnol. Bioeng. 31 (1988) 579–586

Trager, M.;Qazi, G.N.;Buse, R.;Onken U.: Comparison of direct glucose oxidation by Gluconobacter oxydans subsp. suboxydans and Aspergillus niger in a pilot scale airlift reactor. J. Ferm. Bioeng. 74 (1992) 274–281

Wachi, S.;Jones, A.G.;Elson, T.P. Flow dynamics in a draft tube bubble column, using various liquids. Chem. Eng. Sci. 46 (1991) 657–663

Weiland, P.: Influence of draft tube diameter on operation behaviour of airlift loop reactors. Ger. Chem. Eng. 7 (1984) 374–385

Winkler, M.A.: 1990. Problems infermenter design and operation. In: Winkler, M.A. (ed.), Chemical engineering biotechnology. pp. 215–350, Elservier Appl. Sci., New York, 1990

Zuber, N.;Findlay, J.A.: Average volumetric concentration in two-phase flow systems. J. Heat Transfer, (Trans. ASME). 87 (1965) 453–468

Author information

Authors and Affiliations

Corresponding author

Additional information

UCL is the Biotechnology and Biological Sciences Research Council sponsored Advanced Centre for Biochemical Engineering and the Council's support is greatly acknowledged.

Rights and permissions

About this article

Cite this article

Pollard, D.J., Ayazi Shamlou, P., Lilly, M.D. et al. Saccharomyces cerevisiae fermentations in a pilot scale airlift bioreactor: Comparison of air sparger configurations. Bioprocess Engineering 15, 279–288 (1996). https://doi.org/10.1007/BF02391590

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/BF02391590