Abstract

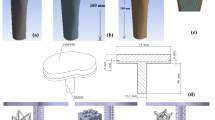

Finite element stress analysis has been applied to examine the stress patterns in a prosthesis requiring fixation in the medullary shaft of a long bone. No specific prosthesis is considered but rather a generally applicable geometry has been chosen. This consists of a cylindrical section of cortical bone within which is implanted a prosthesis composed of a solid central rod surrounded by a porous coating. The finite element analysis utilized an axisymmetric model to determine the distribution of stresses throughout the system. The effect of changes in length of prosthesis, thickness of porous coating, depth and type of tissue ingrowth, and type of porous coating material were studied under conditions of axisymmetric loading. The results indicate that with complete bone ingrowth, the maximum shear stress and the distance necessary for load transfer are both independent of implant length. However, with incomplete ingrowth, increasing implant length reduces shear. Incomplete growth also produces lower shear stresses but higher shear strains in areas without ingrowth. In addition, a porous polyethylene coating gives a more even load transfer and lower shear than a porous coating of a high modulus material.

Similar content being viewed by others

References

Ghista, D. N., Kobayashi, A. S., and Davids, N. Analyses of some biomechanical structures and flows by computer-based finite element method.Computers in Biology and Medicine 1975,5, 119–161.

Hentrich, R. L., Graves, G. A., Stein, H. G., and Bajpai, P. K. An evaluation of intert and resorbable ceramics for future clinical orthopedic applications.Journal of Biomedical Materials Research 1971,5, 25–51.

Herrman, G., and Liebowitz, H. Mechanics of bone fracture. In H. Liebowitz (Ed.),Fracture. New York: Academic Press, 1972.

Homsy, C. A., Kent, J. N., and Hinds, E. C. Materials for oral implantation—biogogical and functional criteria.Journal of the American Dental Association 1973,86, 817–832.

Hulbert, S. F., Cooke, F. W., Klawitter, J. J., Leonard, R. B., Sauer, B. W., Moyle, D. D., and Skinner, H. B. Attchment of prostheses to the musculoskeletal system by tissue ingrowth and mechanical interlocking.Journal of Biomedical Materials Research Symposium No. 4 1973, 1–23.

Katz, J. L. Hard tissue as a composite material-I. Bounds on the elastic behavior.Journal of Biomechanics 1971,4, 455–473.

Klawitter, J. J.A basic investigation of bone ingrowth into a porous material. Ph.D. Thesis, Clemson Univ., 1969.

Klawitter, J. J., and Hulbert, S. F. Application of porous ceramics for the attachment of load bearing internal orthopedic appliances.Journal of Biomedical Materials Research Symposium No. 2, 1971, 161–229.

Moyle, D. D., Klawitter, J. J., and Hulbert, S. F. Mechanical properties of the bone-porous biomaterial interface: elastic behavior.Journal of Biomedical Materials Research Symposium No.4, 1973, 363–382.

Nilles, J. L., Karagianes, M. T., and Wheeler, K. R. Porous titanium alloy for fixation of knee prostheses.Journal of Biomedical Materials Research Symposium No. 5, 1974, 319–328.

Parker, E. R. (Ed.)Materials data book for engineers and scientists. New York: McGraw-Hill, 1967.

Predecki, P., Stephan, J. E., Auslaender, B. A., Mooney, V. C., and Kirkland, K. Kinetics of bone growth into cylindrical channels in aluminum oxide and titanium.Journal of Biomedical Materials Research 1972, 6, 375–400.

Sandiford, D. J. H., and Willbourn, A. H. General mechanical properties. In A. Renfrew and P. Morgan (Eds.),Polythene: the technology and uses of ethylene polymers. New York: Interscience, 1960.

Sauer, B. W., Weinstein, A. M., Klawitter, J. J., Hulbert, S. F., Leonard, R. B. and Bagwell, J. G. The role of porous polymeric materials in prosthesis attachment.Journal of Biomedical Materials Research Symposium No. 5, 1974, 145–153.

Sweeney, A. W., Kroon, R. P., and Byers, R. K.Mechanical characteristics of bone and its constituents. ASME Paper 65-WA/HUF-7, 1965.

Zienkiewicz, O. C.The finite element method in engineering science. London: McGraw-Hill, 1971.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Anand, S.C., John, K.R.S., Moyle, D.D. et al. Stress distribution in porous surfaced medullary implants. Ann Biomed Eng 5, 410–420 (1977). https://doi.org/10.1007/BF02367319

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF02367319