Abstract

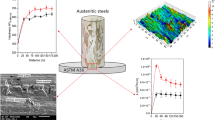

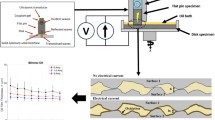

We establish that the time to fracture of specimens made of 8Mn−8Ni−4Cr steel decreases in tap water at high stresses by a factor of 2.5 and, in the course of electrolytic hydrogenation, by a factor of 35–50 as compared with that obtained in tests in twice-distilled water. The use of a hardening surface treatment and protective coatings under the same conditions increases the long-term strength by a factor of 1.5–2. A combined plasma Al+V2O5 coating with subsequent soaking with epoxy compound preserves the plastic characteristics of steel and, hence, increases the time to fracture in the best way. The application of plasma nitride (TiN+CrN+NbN) coatings on the thread and mounting surfaces of elements of a rotor shroud unit gives them a high hardness and resistance to dripping and scoring and prevents the penetration of hydrogen-containing media into the base.

Similar content being viewed by others

References

GOST 10145-81.Metals. A Method for Testing for Long-Term Strength [in Russian], Introduced 01.07.82 (1982).

G. S. Pisarenko and V. A. Strizhalov,Experimental Methods in Mechanics of Deformable Solids [in Russian], Naukova Dumka (1986).

V. I. Pokhmurskii,An Installation for Testing for Long-Term Strength [in Russian], Inventor's Certificate 157144 SSSR, MKI G 01 n, No. 800074/25-8, Announced 24.10.62, Published 25.11.63, Bull. No. 17 (1963).

M. O. Speidel, “Nichtmagnetisierbare Stahle für Generator-Kappenringe, ihr Widerstand gegen Spannungsribkorrosion und Wassertoffversprödung,”VGB Kraft-Werktechnik,61, No. 5, 417–424 (1981).

O. I. Balyts'kyi, “The long-tern strength of high nitrogen steels in aqueous media,” in:Proceedings of the 3rd International Conf.-Exhibition “Corrosion-96” on Problems of Corrosion and Anticorrosion Protection of Structural Materials (L'viv, May 1996) [in Ukrainian], Karpenko Physicomechanical Institute, Ukrainian Academy of Sciences, L'viv (1996), pp. 104–105.

V. I. Pokhmurskii, N. A. Grekov, and E. P. Silina, “The long-term strength of nitrogen corrosion-resistant tire steels,” in:Abstracts of the Second Conf. on High Nitrogen Steels (Kiev, April 1992), [in Russian], Kiev (1992), p. 94.

A. I. Balitskii, “Long-term strength of high nitrogen steels in water and chloride solutions,” in:Proceedings of the 5th International Conf. of High Nitrogen Steels, Transaction Technical Publication, Zürich (1999), pp. 539–544.

N. A. Waterman and M. F. Ashby,The Materials Selector on CD-ROM, CRC, London (1999), 8 MB RAM.ISBN: 0-4127-9250-8.

Standard Specification for Alloy Steel Forgings for Nonmagnetic Retaining Rings for Generators. ASTM Designation: A 289-70a, Annual Book of ASTM Standards (1975).

Antiemergency Instruction No. Ts-01-89 (é):On the Prevention of Damages of Shroud Rings of Rotors of Turbogenerators Caused by Corrosion Cracking [in Russian], Approved 16.02.89, Ministry of Power Engineering and Electrification of USSR, Moscow (1989).

A. I. Balitskii, V.I. Pokhmurskii, V. V. Fedorov, and L. I. Voloshyn, “Hydrogen effects on the physicomechanical properties of protective coatings and oxygen films on austenitic steels,” in:Abstracts of the Fifth International Conf. “Hydrogen Effect of Material Behavior” (Jackson Lake Lodge, Wyoming, September 1994) (1994), p. 14.

A. I. Balitskii, V. N. Zitomerskii, and V. A. Balitskaya, “Phase state and properties of nitride-titanium-chromium condensates on steel,” in:Interfaces, Structural Defects, and Properties of Metals and Alloys, Abstracts of a Joint Meeting of Three Regular All-Union Sem. “Diffraction Methods of Investigation of Distorted Structures,” “Actual Problems of Strength,” and “Physicotechnical Problems of Surface of Metals” [in Russian], Cherepovets State Polytechnic Institute, Cherepovets (1988), p. 83.

A. I. Balitskii, V. I. Pokhmurskii, V. M. Bykov, V. N. Zhitomirskii, K. B. Katsov, and V. G. Makarenko,Coating on Steel Products [in Russian], Inventor's Certificate 1461028 SSSR MKI, S23S 14/00, No. 4228811/31-02, Announced 18.03.87, Registered 25.10.87 (1987).

A. I. Balitskii, A. G. Gavrilov, G. V. Galitskaya, and V. N. Zhitomirskii, “Phase composition and properties of wear-resistant coatings based on Ti−Nb−Cr−N,” in:Means of Improvement of the Efficiency of Manufacture and Application of Instruments with Wear-Resistant Coating [in Russian], VNIITÉMR, Moscow (1990), pp. 151–156.

V. I. Tkachev, V. I. Kholodnyi, and I. N. Levina”The Workability of Steels and Alloys in a Hydrogen Medium [in Russian], Karpenko Physicomechanical Institute, Ukrainian Academy of Sciences, L'viv (1999).

H. J. C. Speidel, P. J. Ugowitzer, P. Ernst, and M. O. Speidel, “Properties of cold worked high nitrogen chromium based alloys,” in:Proceedings of the 5th International Conf. of High Nitrogen Steels, Transaction Technical Publication, Zürich (1999), pp. 214–248.

V. G. Gavriliuk and H. Berns,High Nitrogen Steels, Springer-Verlag, Berlin (1999).

Additional information

Karpenko Physicomechanical Institute, Ukrainian Academy of Sciences, L'viv. Translated from Fizyko-Khimichna Mekhanika Materialiv, Vol. 35, No. 4, pp. 37–42, July–August, 1999.

Rights and permissions

About this article

Cite this article

Balyts'kyi, O.I. Influence of hydrogen on the long-term strength of tire steels. Mater Sci 35, 485–490 (1999). https://doi.org/10.1007/BF02365745

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF02365745