Abstract

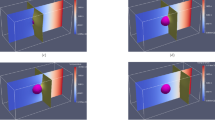

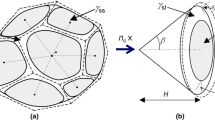

We study the influence of a concentration of stresses in the vicinity of grain-boundary microvoids on their growth by the diffusion mechanism. For this purpose, we use the boundary-value diffusion problem formulated earlier on the basis of thermodynamical analysis of the “metal-microvoid” two-phase system. The distribution of stresses in the vicinity of microvoids, which is required to solve the problem, is determined by the method of finite elements. The results of calculations demonstrate that, at a high concentration of microvoids on the boundary of a grain, the influence of concentration of stresses is insignificant. Only for large values of the relative radius of microvoidsR/λ and a low concentration of microvoids (λ≥50μm) is the effect of concentration of stresses as large as 15–20%.

Similar content being viewed by others

References

M. F. Ashby, “Mechanisms of deformation and fracture,”Adv. Appl. Mech.,23, 117–177 (1983).

J. Friedel,Dislocations, Pergamon Press, Oxford (1964).

D. Hull and D. E. Rimmer, “The growth of grain-boundary microvoids under stress,”Philos. Mag.,4, 673–687 (1959).

J. Raj and M. F. Ashby, “Intergranular fracture at elevated temperature,”Acta Metall.,23, 653 (1975).

A. Needleman and J. R. Rice, “Plastic creep flow effect in the diffusive cavitation of grain boundaries”Acta Metall.,28, 1315–1332 (1980).

I. D. Skrypnyk and A. H. Nykyforchyn, “Modelling of crack propagation in damaged material under creep,” in:Proc. of Int. Symp. “Material Ageing and Life Extension” (1995, Milan, Italy), Vol. 2, 1241–1250 (1995).

M. W. D. van der Burg, E. van der Giessen, and R. C. Brouwer, “Investigation of hydrogen attack in steels 2.25Cr-1Mo with a high-triaxiality microvoid growth model,”,Acta Metall.,44, 2, 505–518 (1996).

I. D. Skrypnyk, “High temperature microvoids growth due to grain boundary diffusion,” in: O. M. Romaniv and S. Ya. Yarema (editors),Fracture Mechanics, Strength and Integrity of Materials, L'viv (1996), pp. 157–168.

G. M. Nykyforchyn, I. D. Skrypnyk, V. B. Lutchyn, “Estimation of the rate of diffusion growth of microvoids with consideration of the concentration of stresses in their vicinity,”Fiz.-Khim. Mekh. Mater.,34, No. 2, 49–55 (1998).

MARC.Volume A: Theory and User Information, Version 7, Palo Alto, USA (1997).

MARC.Volume B: Element Library, Version 7, Palo Alto, USA (1997).

E. I. Krutasova,Reliability of Metals for Equipment, in Power Engineering [in Russian], Énergoizdat, Moscow (1981).

Additional information

Karpenko Physicomechanical Institute, Ukrainian Academy of Sciences, L'viv. Translated from Fizyko-Khimichna Mekhanika Materialiv, Vol. 35, No. 1, pp. 43–46, January–February, 1999.

Rights and permissions

About this article

Cite this article

Skrypnyk, I.D., Lutchyn, V.B. & Student, O.Z. Numerical simulation of diffusion growth of a grain-boundary microvoid. Mater Sci 35, 42–47 (1999). https://doi.org/10.1007/BF02355600

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF02355600