Abstract

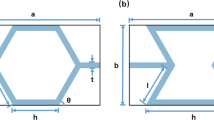

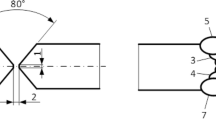

Graphite/epoxy buffer strip panels were subjected to a fatigue loading spectrum, moisture conditioning, or heating and then statically tested in tension to determine their residual strengths. The specimens were made with T300/5208 graphite/epoxy in a 16-ply quasi-isotropic layup, [45/0/ - 45/90]2s, with two different buffer strip materials: Kevlar-49 or S-glass. Each panel was cut in the center to represent damage.

The panels made from each buffer strip material were divided into two test conditions: those panels tested at room temperature and those tested at 82°C. Each test condition was further divided into two groups, panels tested at ambient conditions and panels tested after moisture conditioning. Thus, there were four combinations of preconditioning and test condition: (1) ambient condition tested at room temperature, (2) moisture conditioned tested at room temperature, (3) ambient condition tested at 80°C, and (4) moisture conditioned tested at 82°C. After preconditioning and fatigue loading, all specimens were statically loaded in tension to failure to determine their residual strengths.

After fatigue loading, the buffer strips arrested the crack growth and increased the residual strengths significantly over those of plain laminates without buffer strips under all conditions, with one exception. For the S-glass buffer strip panels with moisture conditioning, the buffer strip arrested the crack growth, but the residual strength was increased only slightly over the strength of a plain laminate. The stiffness of the panels was not affected by the fatigue cycling. Repeated fatigue cycling did not produce any damage growth at the crack tips.

Similar content being viewed by others

References

Poe, C.C., Jr. andKennedy, J.M., “An Assessment of Buffer Strips for Improving Damage Tolerance of Composite Laminates,”J. Comp. Mat. Suppl.,14,57–70 (1980).

Bigelow, C.A., “Fatigue of Graphite/Epoxy Buffer Strip Panels With Center Cracks,” NASA TM-87595 (Aug. 1985).

Bigelow, C.A., “Effects of Moisture, Elevated Temperature, and Fatigue Loading on the Behavior of Graphite/Epoxy Buffer Strip Panels with Center Cracks,” NASA TM-100558 (Feb. 1988).

Lowak, H., de Jonge, J.B., Franz, J. and Schutz, D., “MINI-TWIST A Shortened Version of TWIST,” Nationaal Lucht- En Ruimtevaartlaboratorium, NRL MP 79018 u, ICAF Document 1147 (Jan. 1979).

Williams, J.G., Anderson, M.S., Rhodes, M.D., Starnes, J.H., Jr. and Stroud, W.J., “Recent Developments in the Design, Testing and Impact-Damage Tolerance of Stiffened Composite Panels,” NASA TM-80077 (April 1979).

Lee, B.L., Lewis, R.W. and Sacher, R.E., “Environmental Effects on the Mechanical Properties of Glass Fiber/Epoxy Resin Composites,” ICCM/2: Proc. 1978 Int. Conf. on Comp. Mat., Met. Soc. of AIME, 1560–1583 (1978).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Bigelow, C.A. Effects of fatigue and environment on residual strengths of center-cracked graphite/epoxy buffer strip panels. Experimental Mechanics 29, 90–94 (1989). https://doi.org/10.1007/BF02327788

Received:

Accepted:

Issue Date:

DOI: https://doi.org/10.1007/BF02327788