Abstract

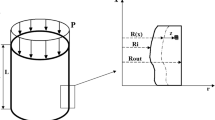

Creep-buckling tests were conducted on aluminum alloy 2024-0 circular cylinders in axial compression at 500° F having nominalR/t values of 90 and 50. Creep-buckling times for a variety of applied creep-stress values were compared with theoretical predictions of Gerard's unified theory of creep buckling of columns, plates and shells. In this theory, creep-buckling solutions are analogous to plastic-buckling solutions, provided that the material parameters used in the theoretical relation are developed from constant-strain-rate stress-strain data derived by a graphical process from compressive-creep data. The theoretical data were evaluated using appropriate classical plastic-buckling theory and previously obtained creep data on the 2024-0 aluminum material at 500° F.

End shortening of the cylinders was autographically recorded during the tests and creep-buckling times were obtained from an analysis of the end-shortening record. A comparison of theory and test data indicated that the theory was somewhat conservative in predicting creep-buckling times. The discrepancy may have been due, in part, to the uncertainty in determining the precise time at which the experimental cylinders buckled. The cylinders withR/t∼90 buckled in the axisymmetric mode for the lower creep stresses while, forR/t∼50, all buckling occurred in the axisymmetric mode.

Similar content being viewed by others

References

Gerard, G., “A Unified Theory of Creep Buckling of Columns, Plates, and Shells,” Proc. Internatl. Coun. Aero. Sci., Third Congress, Stockholm—1962, Spartan Books Inc., Washington, D. C.

Gerard, G., “Theory of Creep Buckling of Perfect Plates and Shells,”Jnl. Aero. Sci.,29 (9),1087–1090 (1962).

Gerard, G. andPapirno, R., “Classical Columns and Creep,”Jnl. Aero. Sci.,29 (6),680–688 (1962).

Rabotnov, G. N. andShesterikov, S. A., “Creep Stability of Columns and Plates,”Jnl. Mech. and Phys. Solids,6,27–34 (1957).

Papirno, R. and Gerard, G., “Correlation of Plate Creep Buckling Theory with Experiments on Long Plates of Aluminum Alloy 2024-0 at 500° F,” ASD-TDR-62-865 (1962).

Samuelson, A., “An Experimental Investigation of Creep Buckling of Circular Cylindrical Shells Subject to Axial Compression,” Aero. Res. Inst. Sweden (FFA), Report No. 98 (1964).

Diamont, E. S., “Axisymmetric Creep in Cylindrical Shells,”AIAA Jnl. 5 (10),1870–1876 (1967).

Gerard, G., “A Creep Buckling Hypothesis,”Jnl. Aero. Sci. 23 (9),879–883 (1965).

Gerard, G. andGilbert, A. S., “A Critical Strain Approach to Creep Buckling of Plates and Shells,”Jnl. Aero. Sci. 25 (7),429–435 (1958).

French, F. W. andPatel, S. A., “A Creep Buckling of Cylindrical Shells Subjected to Uniform Axial Compression,”PIBAL Report No. 489, Polytech. Inst. Brooklyn (1959).

Samuelson, A., “Creep Deformation and Buckling of a Circular Cylindrical Shell under Axial Compression,” Aero. Res. Inst. Sweden (FFA), Report No. 108 (1967).

Papirno, R., “Time Dependent Compression Properties of Aluminum Alloy 2024-0 at 500° F (533K),” Allied Research Associates Report ARA 290-4, also AROD-5469-1 AD-642159, N67-15340, 1966.

Papirno, R., “Experimental Plastic Buckling of Aluminum Cylinders at 500° F,”AIAA Jnl.,5 (12),2266–2267 (1967).

Batterman, S. C., “Plastic Buckling of Compressed Cylindrical Shells,”AIAA Jnl.,3 (2),316–325 (1965).

Gerard, G. and Becker, H., “Handbook of Structural Stability, Part III—Buckling of Curved Plates and Shells,” NACA TN 3783, 28–30, 99 (1959).

Gerard, G., “Plastic Stability Theory of Geometrically Orthotropic Plates and Cylindrical Shells,”Jnl. Aero. Sci.,29 (8),956–962 (1962).

Gerard, G., “Compressive Stability of Orthotropic Cylinders,”Jnl. Aero. Sci.,29 (10),1171–1180 (1962).

Papirno, R. andGoldman, R., “Low Strain Rate Plastic Buckling of Aluminum Cylinders at 500° F,”AIAA Jnl.,6 (9),1794–1796 (1968).

Author information

Authors and Affiliations

Additional information

The study described here was performed at Allied Research Associates, Inc., under sponsorship of the U. S. Army Research Office, Durham, North Carolina, Project No. ARO-D-5469-E.

Rights and permissions

About this article

Cite this article

Papirno, R., Goldman, R. Experimental creep buckling of aluminum cylinders in axial compression. Experimental Mechanics 9, 356–365 (1969). https://doi.org/10.1007/BF02327713

Issue Date:

DOI: https://doi.org/10.1007/BF02327713