Abstract

The feasibility of using cyclic thermal stress or hydrostatic pressure to generate a fatigue crack in a large test-rotor blank is demonstrated. Test rotors, having test notches with fatigue-crack terminations, were spun to fracture to determine optimum test-notch design. It was found that, for the other test-notch dimensions held, it was necessary to extend the fatigue crack a minimum of 0.1 in. from the machined portion of the test notch to obtain a most effectively notched test rotor. In another series of tests, the influence of temperature on brittle-fracture strength of a Cr-Mo-V steel under plane strain was evaluated. It was found that, although there is a significant increase in fracture strength with increasing temperature, no knee in the curve is apparent in the vicinity of the conventionally measured transition temperatures ofNDT andT 50. Also, design against brittle fracture is still required at temperatures aboveNDT andT 50.

Similar content being viewed by others

Abbreviations

- C :

-

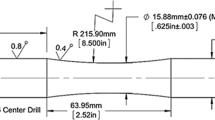

notch length of test rotor (total), in

- E :

-

modulus of elasticity, psi

- e :

-

elongation in 2-in. gage length, percent

- G C :

-

fracture toughness of material,\(\begin{gathered} \hfill \\(\pi \sigma _o ^2 C/2E) (1 - \nu ^2 ) \hfill \\ \end{gathered} \), in. lb/in.2

- G IC :

-

fracture toughness of material under plane strain,\(G_c /[1 + (1.4/\alpha _1 ^2 )]\), in. lb/in.2

- h :

-

length of test rotor, in

- K IC :

-

stress-intensity factor under plane strain,\(10^{ - 3} [EG_{IC} /(1 - \nu ^2 )]^{1/2} ,ksi\sqrt {in.} \)

- l :

-

length of fatigue crack forming one of the test-notch terminations, in

- N :

-

fracture speed of test rotor, rpm; ω=2πN/60, rad/sec

- NDT :

-

nil-ductility transition temperature, °F

- R i :

-

inside radius of test rotor, in.; ID=2R i , in

- R i :

-

outside radius of test rotor, in.; OD=2R o , in

- RA :

-

reduction of area, percent

- T :

-

test temperature, °F

- ΔT :

-

temperature difference between that at the hole wall and that remote from the hole, °F

- T 50 :

-

Charpy Vee-notch 50-percent shear-fracture appearance transition temperature, °F

- α:

-

thermal coefficient of expansion, (in./in.)/°F

- α1 :

-

constraint index,\(h\sigma _{y^2 } /EG_C \), dimensionless

- ε:

-

strain at the hole wall, 102 σ/E, percent

- ν:

-

Poisson's ratio=0.3 (for steel)

- ρ:

-

mass density of material, lb sec2/in.4=0.283/386

- σ:

-

tangential stress at the hole wall,EαΔT/(1−ν), psi

- σ aν :

-

average net-section tangential stress corresponding to the fracture speed of the test rotor,\(\frac{{\rho \omega ^2 }}{3}(\frac{{R_o ^3- R_i ^3 }}{{R_o- C/2}}),psi\)

- σ o :

-

nominal fracture stress. Tangential stress at center of solid rotor corresponding to the fracture speed of the test rotor,\(\frac{{(3 - 2\nu )}}{{8(1 - \nu )}}\rho \omega ^2 R_o ^2 \), psi

- σ4 :

-

nominal stress correction for uniformC of 4.0 in.,\(\sigma _o (C/4)^{1/2} \)

- σ IO :

-

nominal fracture stress for conditions of complete plane strain andC=4 in.,\(\alpha _4 /(1 + \frac{{1.4}}{{\alpha _1 ^2 }})^{1/2} \), psi

- σ y :

-

yield strength of material, psi (0.2-percent offset)

- σ u :

-

ultimate strength of material, psi

References

Irwin, G. R., “Fracture Mode Transition for a Crack Traversing a Plate,” Met. Eng. Conf., ASME, Albany, N. Y. (April 29–May 1, 1959).

Cooper, G., Sankey, G. O. and Wessel, E. T., Discussion of paper by Brothers, A. J., Newhouse, D. L. and Wundt, B. M., “Results of Bursting Tests of Alloy Steel Disks and Their Application to Design Against Brittle Fracture,” ASTM Annual Meeting, Purdue University (June 13–18, 1965).

Wessel, E. T., “The Influence of Pre-Existing Sharp Cracks on Brittle Fracture of a Nickel-Molybdenum-Vanadium Forging Steel,”ASTM Proc 60,721–732 (1960).

Winne, D. H. and Wundt, B. M., “Application of the Griffith-Irwin Theory of Crack Propagation to the Bursting Behavior of Disks, Including Analytical and Experimental Studies,” Trans. ASME,80, (1958).

Clark, W. G., Jr., and Ceschini, L. J., “Fatigue Precracking of Spin-Burst Toughness Specimens,” presented at SESA Spring Meeting, Paper No. 1357A, Albany, N. Y. (May 7–10).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Sankey, G.O. Spin tests to determine brittle fracture under plane strain. Experimental Mechanics 8, 529–538 (1968). https://doi.org/10.1007/BF02327515

Issue Date:

DOI: https://doi.org/10.1007/BF02327515