Abstract

A study on the tightening characteristics of bolt-nut-washer assemblies was undertaken after a preliminary literature survey showed different opinions to exist on the effect of several commonly encountered factors on the torque-tension relationship.

The test program included tightening bolts up to the yield point under a planned series of combination of factors, and recording nut-tightening torque, bolt torque and tension.

The main factors tested were:

-

(a)

Plating of the mating surfaces of bolt, nut and washer

-

(b)

Lubrication of the interfaces.

Among the subsidiary factors considered were the hardness and yield stress of the materials and the class of fit of the threads.

The tests were planned and analyzed with statistical techniques in order to obtain estimates of the effects of each factor and the more important interactions (singled out of the total number in a series of pilot tests) as well as of the errors to be considered for the tests of significance. The analysis was carried out with mathematical and graphical methods giving accurate results in an easily understandable form from a reasonably small number of experimental data. The isolation of the main effects and interactions was achieved with no loss of general applicability of the results, taking advantage of the peculiar properties of the factorial experimental design adopted.

A comparison between the torque wrench and the turn-of-nut method of bolt-tightening is made in terms of closeness of bolt tension control.

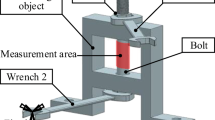

A simple bolt-testing machine was built for the tests. A motor-driven wrench with a strain-gage bridge measuring the input torque tightened the nut at low speed while a two-component strain-gage transducer measured bolt torque and tension. Provision was also made for measuring the angle of rotation of the nut and the torsion of the bolt's shank.

Similar content being viewed by others

References

Adler, J. F., “Exploratory Tests on Friction Grip Bolted Joints,” Inst. Structural Engrs., Proc. Symp. H. S. Bolts, 37, London (1959).

Drew, F. P., “Tightening High-Strength Bolts,” Proc. paper No. 786, ASCE,81 (August 1955).

Pauw, A., and Howard, L. I., “Tension Control for High Strength Structural Bolts,” Proc. 1955 AISC National Engrg. Conf. (1956).

Hanneman, W. M., “How Plated Finishes Affect Bolt Tightening,”Fasteners,16 (1–2),7 (1961).

Specification for Assembly of Structural Joints using High Strength Bolts, Rsch Council Riveted and Bolted Structural Joints, Cleveland (1954).

Preliminary Directives for the Calculation, Design and Assembly of Non-Slip Bolted Connexions for Steel Structures, Bridges and Cranes, Stahlbau-Verlags G.m.b.H., Köln (1956).

Munse, W. H., Wright, D. T., andNemark, N. M., “Laboratory Tests of Bolted Joints,”Trans. ASCE,120,1296 (1955).

Martin, H., “The Properties of High Strength Bolts,” Inst. Structural Engrs., Proc. Symp. on H. S. Bolts, 96, London (1959).

Pickel, W. F., “Tightening Characteristics of Nut and Stud Assemblies,” Product Engrg., 98 (January 1949).

Rabinowicz, E., “A Study on the Stick-Slip Process,” Proc. 1957 Symposium on Friction and Wear (R. Davies ed.), Elsevier (1959).

Levi, R., “Misura rapida del diametro medio di filettature interne,” Ingegneria Meccanica (Novembre 1965).

Fisher, R. A., The Design of Experiments, Sec. 39–40, 7th ed. Oliver and Boyd, Edinburgh (1960).

Natrella, M. G., Experimental Statistics, Sec. 12–4, N.B.S. Handbook 91, Washington (1963).

Statistical Engineering Lab., Fractional Factorial Experiment Designs for Factors at Two Levels, Sec. 5, 2.6.16, N.B.S. Applied Mathematics Series 48, 2nd ed., Washington (1962).

Fisher, R. A., Statistical Methods for Research Workers, Sec. 26, 13th ed., Oliver and Boyd, Edinburgh (1958).

Cochran, W. G., andCox, G. M., Experimental Designs, Sec. 3.87, 2nd ed., J. Wiley, New York (1957).

Yates, F., The Design and Analysis of Factorial Experiments, Tech. Comm. No. 35, Imp. Bur. of Soil Science, Harpenden (1937).

Bartlett, M. S., “Properties of Sufficiency and Statistical Tests,”Proc. Royal Soc. A.,160,268 (1937).

Davies, O. L. (ed.),Design and Analysis of Industrial Experiments App. 7c, 2nd ed., Oliver and Boyd, Edinburgh (1963).

Johnson, L. G., Theory and Technique of Variation Research, Elsevier, Amsterdam (1964).

Maney, G. A., Predicting Bolt Tension,Fasteners,3 (5) (1947).

Goodier, J. N., “Distribution of Load on the Threads of Screws,”Trans. ASME, Jnl. Appl. Mech. 7 (1)10 (1940).

Discussion of Session Two, Bolts and Wrenches, Inst. of Structural Engrs., Proc. Symp. on H. S. Bolts, 131, London (1959).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Bray, A., Levi, R. Factors affecting the tightening characteristics of bolts. Experimental Mechanics 6, 409–419 (1966). https://doi.org/10.1007/BF02326286

Issue Date:

DOI: https://doi.org/10.1007/BF02326286