Abstract

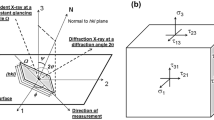

The three-dimensional residual-stress condition of several martensitic stainless-steel sheets given various combinations of surface treatments was studied by an X-ray-diffraction method. The stress tensors in the near-surface region, approximately 12 micrometers (0.012 mm) deep, were calculated after obtaining the strain tensors through application of the differential method and an advanced X-ray-diffraction stress-measurement instrument. The advanced instrument collected the data in a few hours—a task that normally requires several days to a few weeks-and provided accuracies on the order of ±14 MPa (2 ksi). The surface treatments to the sheets included various combinations of mechanical polishing and vapor blastiing; all produced substantial compressive stresses in the plane and perpendicular to the surface. The mill-annealed specimen showed nearly zero residual stress prior to mechanical polish or vapor blasting. The resulting tensor-stress data were compared with data obtained through single-exposure-technique calculations which assume a plane-stress state on the surface.

Similar content being viewed by others

References

Ruud, C.O., “A Review of Selected Non-Destructive Methods for Residual Stress Measurement,” NDT Int., 15–23 (Feb. 1982).

Ruud, C.O., “Position-Sensitive Detector Improves X-Ray Powder Diffraction,” Industrial Res. and Dev., 84–87 (Jan. 1983).

Dölle, H., “The Influence of Multiaxial Stress State, Stress Gradients and Elastic Anisotropy on the Evaluation of (Residual) Stress by X-Ray,”J. Appl. Cryst.,12,489–510 (1979).

Cullity, B.D., “Some Problems in X-Ray Stress Measurements,”Adv. in X-Ray Anal.,20,Plenum Press,259–271 (1977).

Soc. Automotive Eng., “Residual Stress Measurement by X-Ray Diffraction-SAE J784a,”Soc. Automotive Eng., Inc., Warrendale, PA (1971).

Cullity, B.D., Elements of X-Ray Diffraction, 2nd ed., Addison-Wesley, Reading, MA (1978).

Prevey, P.S., “A Method of Determining the Elastic Properties of Alloys in Selected Crystallographic Directions for X-Ray Diffraction Residual Stress Measurement,” Adv. in X-Ray Anal.,20 (1977).

Torbaty, S., Sprauel, J.M., Maeder, G. andMarkho, P.H., “On the X-Ray Diffraction Method of Measurement of Triaxial Stresses with Particular Reference to the Angle Two Theta-Zero,”Adv. in X-Ray Anal.,26,245–253 (1983).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Ruud, C.O., Chen, P.C. Application of an advanced XRD instrument for surface stress-tensor measurements on steel sheets. Experimental Mechanics 25, 245–250 (1985). https://doi.org/10.1007/BF02325093

Received:

Accepted:

Issue Date:

DOI: https://doi.org/10.1007/BF02325093