Abstract

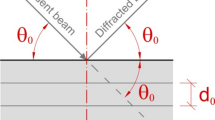

The instrumentation, technique, and procedures are described for the nondestructive measurement of residual stresses on the inside surface of pipe as small as 10 in. in diam. The instrument is based upon a unique position-sensitive scintillation X-ray detector which provides for the most compact X-ray stress-measurement instrument available since the introduction of film cameras four decades ago. This instrument is capable of applying the single-exposure technique of X-ray stress measurements which results in unprecedented rapidity of stress measurement consistent with excellent precision and accuracy. The results of testing the precision and accuracy of the instrument on a zero-stress powder and four-point-bend specimen are given.

Residual stresses in four austenitic stainless-steel girth-welded pipes are presented illustrating the effects of the different welding procedures. The results from the pipes confirm the beneficial residual-stress condition of heat-sink-welding procedures.

Similar content being viewed by others

References

Vaidyanathan, S., Todaro, A.F. and Finnie, I., “Residual Stresses Due to Circumferential Welds”, J. Eng. and Tech., 223–237 (Oct. 1973).

Rybicki, E.F. and Stonesifer, R.B., “Computation of Residual Stresses Due to Multipass Welds in Piping Systems”, ASME 78-PVP-104 (1978).

Cheng, C.F., Ellingson, W.A. and Park, J.Y., “Effect of Residual Stress and Microstructure of Stress Corrosion Cracking of BWR Piping”, Paper presented at NACE Annual Corrosion Conf., Houston, TX (March 22–26, 1976).

chrenko, R.M., “Residual Stress Studies of Austenitic and Ferritic Steels”, Residual Stress in Welded Construction and Their Effects, The Welding Inst., Paper No. 3, 27–37 (Nov. 15–17, 1977).

Imai, K., Itow, H., Kirihara, S., Koyama, T., Marayama, T., Hasaoka, I., Miki, M. and Susaki, R., “Mitigation of Inside Surface Residual Stress of Type 304 Stainless Steel Pipe Welds by Running Water Cooling Method”, 3rd Int. Conf. Weld. in Nuclear Eng., Hamburg (Nov. 28–29, 1978).

Ruud, C.O., “A Unique Position Sensitive Detector for X-Ray Powder Diffraction”, Ind. Res. and Dev. (Jan. 1983).

“Residual Stress Measurement of X-Ray Diffraction — SAE J784a”, Soc. Automotive Eng., handbook supplement, 2nd ed. (Aug. 1971).

Prevey, P.S., “A Method of Determining the Elastic Properties of Alloys in Selected Crystallographic Directions for X-Ray Diffraction Residual Stress”,Advances in X-Ray Analysis, Plenum Press,20,345–354 (1977).

Ruud, C.O. and Barrett, C.S., “Use of Cr K-Beta X-Rays and Position Sensitive Detector for Residual Stress Measurement in Stainless Steel Pipe”, Advances in X-Ray Analysis,22 (1979).

Cullity, B.D., “Elements of X-Ray Diffraction”,2nd ed., Addison-Wesley Publishing Co. Inc., Reading, MA (1978).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Ruud, C.O., DiMascio, P.S. & Melcher, D.M. Nondestructive residual-stress measurement on the inside surface of stainless-steel pipe weldments. Experimental Mechanics 24, 162–168 (1984). https://doi.org/10.1007/BF02325000

Received:

Revised:

Issue Date:

DOI: https://doi.org/10.1007/BF02325000