Abstract

A test fixture was designed and built to evaluate tensile properties at a specific rate of strain in the region from 0.01 to 25 in./in./sec. The specimen is of tubular section and loaded internally by fluid pressure. Details of the design and instrumentation are presented. Test results for annealed 1018 steel are given and compared with results of other investigators. This steel is shown to be strain-rate sensitive in the region tested.

Similar content being viewed by others

Abbreviations

- A :

-

piston area (A g large end,A p small end)

- A m :

-

area of metering orifice

- C v :

-

orifice discharge coefficient

- E :

-

modulus of elasticity

- e :

-

engineering strain

- e o :

-

yield-point strain (e o =0.01)

- e c :

-

critical or necking strain

- \(\dot e\) :

-

engineering strain rate (de/dt)

- \(\dot e_o \) :

-

engineering strain rate at yield point

- K :

-

stress coefficient

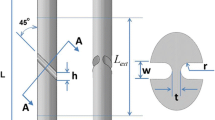

- L e :

-

effective length of speciment

- n :

-

strain-hardening exponent

- P :

-

fluid pressure in specimen

- P o :

-

fluid pressure at yield point

- P g :

-

gas pressure

- Q mo :

-

flow rate of metering fluid at yield

- r o :

-

original inside radius of specimen

- r p :

-

radius of piston

- t :

-

wall thickness of specimen

- u p :

-

velocity of piston

- α:

-

A g /A p , a parameter

- β:

-

a constant

- ε:

-

true strain [ε=ln (1+e)]

- η:

-

P g /P o , a parameter

- λ:

-

stress ratio (\(\sigma _d /\sigma _s \))

- ρ:

-

density of metering fluid

- σ:

-

stress in specimen (circumferential)

- \(\sigma _o \) :

-

stress at yield

- \(\sigma _d \) :

-

dynamic stress

- \(\sigma _s \) :

-

static stress

- ψ:

-

fractional velocity decrease

References

Craft, R. L., “The Analysis and Design of a System for Testing Materials at Intermediate Strain Rates,” Master's Thesis, Dept. of Mech. Eng., Kansas State University, (1969).

Austin, A. L. and Steidell, Jr., R. F., “A Method for Determining the Tensile Properties of Metals at High Rates of Strain,” Proc. ASTM,59,(1959).

Anderson, A. G. H., “A Medium-Speed Tensile Testing Machine and Some Dynamic Data Produced Thereby,” High Speed Testing,4, (1963).

Clark, D. S. andDuwez, P. E., “The Influence of Strain Rate on Some Tensile Properties of Steel,”Proc. ASTM,50,560 (1950).

Chen, H. H., “A Fixture for Testing Materials at Medium Strain Rates,” Master's Report, Dept. of Mech. Eng., Kansas State University, (1963).

Giles, G. L., “Material Properties at Medium Strain Rates,” Master's Report, Dept. of Mech. Engrg., Kansas State University, (1964).

Dieter, C. E., Jr., Mechanical Metallurgy, McGraw-Hill Book Company, Inc., New York, (1961).

Rai, N. S., “Investigation of Some Properties of Mild Steel at Moderate Strain Rates,” Master's Thesis, Dept. of Mech. Engrg., Kansas State University (1969).

Clark, D. S. “The Influence of Impact Velocity on the Tensile Characteristics of Some Aircraft Metals and Alloys,” National Advisory Committee for Aeronautics Technical Note, No. 868 (Oct. 1942).

Campbell, J. D., “The Dynamic Yielding of Mild Steel,”Acta Metallurgical,1,708 (Nov.1953).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Lindholm, J.C., Craft, R.L. Design and evaluation of a testing machine for determining tensile properties of materials at moderate strain rates. Experimental Mechanics 11, 153–160 (1971). https://doi.org/10.1007/BF02324906

Issue Date:

DOI: https://doi.org/10.1007/BF02324906