Abstract

Wildhaber-Novikov gears having circular flanks hold out a very promising future in the field of gearing for power transmission in very heavily loaded machineries. In order to optimize the profile parameters of these gears, a photoelastic investigation was carried out.

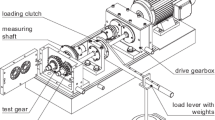

Models of Wildhaber-Novikov gears made of photoelastic material, Araldite-D, were used in the investigation. Included were the models with various profile radii and fillet radii at different pressure angles. The flank and bending stresses of these gears were determined in each case and were compared with those of involute gears.

From this investigation, it was concluded that the load-carrying capacity of circular-arc gears is 3.5 times that of involute gears. It was found that with profile radius up to 1.5 module, the bending stresses of these gears are lower than those of corresponding involute gears, under identical conditions of loading. It was observed that high pressure angles, when used for Wildhaber-Novikov gears having comparatively smaller profile radii, produce high flank stresses. Gears with larger profile radii, at smaller pressure angles were seen to have a high value for the ratio of flank stress to the bending stress. On the other hand, gears with smaller profile radii, at higher pressure angles, were observed to have a smaller value for this ratio of stresses.

Similar content being viewed by others

Abbreviations

- b :

-

face width, mm

- d 1′ :

-

pitch diameter of the pinion, mm

- d 2′ :

-

pitch diameter of the wheel, mm

- h a1 :

-

addendum of the pinion, mm

- h f2 :

-

dedendum of the wheel, mm

- k σ :

-

stress-concentration factor

- m :

-

module, mm

- r f1 :

-

fillet radius of the pinion tooth, mm

- r f2 :

-

fillet radius of the wheel tooth, mm

- s 1 :

-

thickness of the pinion tooth, mm

- s 2 :

-

thickness of the wheel tooth, mm

- α:

-

pressure angle, deg

- p 1 :

-

profile radius of the pinion tooth, mm

- p 2 :

-

profile radius of the wheel tooth, mm

- Δp:

-

difference between the profile radii, mm

- σc:

-

flank stress, Pa

- σb:

-

bending stress, Pa

References

Chironis, N. P., “Design of Novikov Gears,” Product Eng., 91–102 (Sept. 17, 1962).

Allan, T., “Some Aspects of the Design and Performance of Wildhaber-Novikov Gearing,” Proc. Inst. Mech. Engrs., 179 (Part 1) (1964–1965).

Klein, G. J., “The Wildhaber-Novikov System of Gearing,” DME/NAE Quarterly Bulletin, 1965 (1), National Research Council of Canada (April 1965).

Walker, H., “A Critical Look at the Novikov Gear,”The Engineer, London, 209, 725–729 (April 29, 1960).

Johnson, D. C., “Novikov Gear: Gear Teeth with Circular Arc Profiles,” Engineering, 294 (Oct. 2, 1959).

Davies, W. J., “Novikov Gearing,” Machinery, 96 (2461),64–73 (Jan. 13, 1960).

Dobrovolsky, V., et al., Machine Elements, MIR Publishers, Moscow, 318–328 (1963).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Lingaiah, K., Ramachandra, K. Photoelastic optimization of the profiles of Wildhaber-Novikov gears. Experimental Mechanics 16, 116–120 (1976). https://doi.org/10.1007/BF02324896

Issue Date:

DOI: https://doi.org/10.1007/BF02324896