Abstract

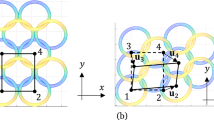

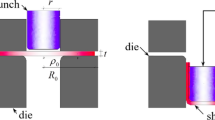

The changes in internal diameter that occur when a hollow disk, or ring, is plastically deformed by axial compression have been proposed as a method for measuring interface friction during metal forming. The adoption of this test method has been delayed because the three-dimensional strains in such rings are not known.

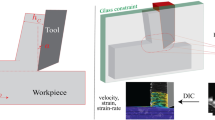

This paper describes how an experimental method using photoplastic simulation was used to obtain the three-dimensional strains for a particular ring geometry. It presents proot of highly nonuniform strains and also shows that the division between flow inward and flow outward occurs at different radii through the thickness of the ring.

Similar content being viewed by others

References

Kunogi, M., “A New Method of Cold Extrusion,”Jnl. of the Sci. and Res. Inst., Tokyo,50,215–246 (1956).

Male, A.T. andCockcroft, M.G., “A Method for the Determination of the Coefficient of Friction of Metals Under Conditions of Bulk Plastic Deformation,”J. of the Inst. of Metals,93,38–46 (1964).

Avitzur, B., “Forging of Hollow Discs,”Israel J. of Tech.,2 (3),295–304 (1964).

Hawkyard, J.B. andJohnson, W., “An Analysis of the Changes in Geometry of a Short Hollow Cylinder During Axial Compression,”Intl. J. of Mech. Sci.,9,163–182 (1967).

Van Sant, O.J., “Mathematical Analysis for Axial Compression of a Flat Ring,”J. of the Inst. of Metals,95,125–127 (1967).

Male, A.T. andDe Pierre, V., “The Validity of Mathematical Solution for Determining Friction from the Ring Compression Test,”J. of Lubric. Tech., Trans. ASME,92 (3),Series F.,389–397 (1970).

Sawl, G., Male, A.T. and De Pierre, V., “A New Method for the Determination of Material Flow Stress Values under Metal Working Conditions,” Air Force Material Laboratory, Technical Report TR-70-19 (1970).

Avitzur, B., “Bulge in a Hollow Disk Forging,” Air Force Material Laboratory, Technical Report TR-69-261 (1969).

Avitzur, B. andSauerwine, F., “Limit Analysis of Hollow Disk Forging, Part I: Upper Bound,”J. of Eng. for Industry, Trans. ASME,100,340–346 (1978).

Sauerwine, F. andAvitzur, B., “Limit Analysis of Hollow Disk Forging, Part 2: Lower Bound,”J. of Eng. for Industry, Trans. ASME,100,347–355 (1978).

De Pierre, V., Gurney, F. and Male, A.T., “Mathematical Calibration of the Ring Test with Bulge Formation,” Air Force Material Laboratory, Technical Report Tr-72-37 (1972).

Liu, J.Y., “An Analysis of Deformation Characteristics and Interfacial Friction Conditions in Simple Upsetting of Rings,”J. of Eng. for Industry, Trans. ASME,94,1149–1155 (1972).

Lee, C.H. andAltan, T., “Influence of Flow Stress and Friction upon Metal Flow in Upset Forging of Rings and Cylinders,”J. of Eng. for Industry, Trans. ASME,94,775–782 (1972).

Chen, C.C. andKobayashi, S., “Rigid Plastic Finite Element Analysis of Ring Compression,”The Amer. Soc. of Mech. Eng., AMD,28,163–174 (1978).

Hill, R.A., “General Method of Analysis for Metal-Working Processes,”J. of the Mech. and Physics of Solids,11,305–326 (1963).

Lahoti, G.O. andKobayashi, S., “On Hill's General Method of Analysis for Metal-Working Processes,”Int. J. of Mech. Sci.,16,521–540 (1974).

Burger, C.P., “Nonlinear Photomechanics,” EXPERIMENTAL MECHANICS,20 (11),381–389 (1980).

Gomide, H.A., Photoplastic Studies of Upset Forging of Rings and of Strip Rolling, Iowa State University, PhD Dissertation (1979).

El-Hout, J.N., A Three-Dimensional Strain Distribution in Hot-Rolled Aluminum by Photoplastic Simulation, Iowa State University, MS Thesis (1977).

Oyinlola, A.K., Strain Distribution Analysis in Ring Upset Forging and Hot-Rolling by Photoplasticity, Iowa State University, PhD Dissertation (1977).

Ramberg, W. and Osgood, W.R., “Description of Stress-Strain Curves by Three Parameters,” U.S. Nat'l. Adv. Comm. for Aero., Technical Note No. 902, (1943).

Freire, J.L.F., “Application of Three-dimensional Photoplasticity to Plane Strain and Axisymmetric Compression Problems,” EXPERIMENTAL MECHANICS,(to be published).

Dally, J.W. andRiley, W.F., Experimental Stress Analysis, McGraw-Hill Book Company, New York (1978).

Durelli, A.J. andParks, V.J., Moiré Analysis of Strain, Prentice-Hall, Inc, Englewood Cliffs, NJ (1970).

Sokolnikoff, I.S., Mathematical Theory of Elasticity, McGraw-Hill Book Company, New York (1956).

Author information

Authors and Affiliations

Additional information

H.A. Gomide (SESA Member) was formerly associated with Iowa State University, Department of Engineering Science & Mechanics

Rights and permissions

About this article

Cite this article

Gomide, H.A., Burger, C.P. Three-dimensional strain distributions in upset rings by photoplastic simulation. Experimental Mechanics 21, 361–370 (1981). https://doi.org/10.1007/BF02324797

Received:

Accepted:

Issue Date:

DOI: https://doi.org/10.1007/BF02324797