Abstract

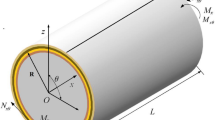

In the companion paper we describe a new experimental technique for resolving the phase difference between two electrical sinusoidal signals to an accuracy of 2π/216 or 9.587×10−7 radians. In this paper we demonstrate the use of that technique in measuring the intrinsic material damping of metal-matrix composites in axial tension using strain gages. In particular, the influence of ply, angle, θ, on the axial damping of a Pitch 55 graphite/6061 aluminum [±θ]s laminate is studied at a fixed frequency, a fixed strain level, and at room temperature. Recently, Ni and Adams proposed a model for predicting theflexural damping of a liminate from the flexural damping properties of a lamina. A close agreement between the model and the experiment was observed. As far as we know these are the first measurements of intrinsic material damping of metal-matrix composites.

Similar content being viewed by others

References

Kinra, V.K. and Wren, G.G., “Axial Damping in Metal-matrix Composites. I: A New Technique for Measuring Phase Difference to 10 −4 Radians,”Experimental Mechanics,32 (2), (June 1992).

Gibson, R.F., “Recent Research on Dynamic Mechanical Properties of Fiber Reinforced Composite Structures,”Shock and Vib. Dig.,15 (2), (Feb. 1983).

Lin, C.H. andPlunkett, R., “A Low-Frequency Axial Oscillation Technique for Composite Material Damping Measurement,”J. Comp. Mat.,23,92–105 (Jan. 1989).

Allard, L.F., Rawal, S.P. and Misra, M.S., “Characterization of Interfaces in Metal Composites,” J. Metals, 40–42 (Oct. 1986).

Misra, M.S., “Metallurgical Characterization of the Interfaces and the Damping Mechanisms in Metal Matrix Composites,” Progress Rept. MCR-85-605, Issue 3, Office of Naval Research, Contract No. N00014-84-C-0412 (June 1986).

Lo, J., Finello, D., Schmerling, M. andMarcus, H.L., “Interface Structure of Heat-Treated Aluminum-Graphite Fiber Composites,”Mechanical Eng. Dept., Materials Sci. and Eng., Univ. of Texas, Austin (1985).

Wren, G.G. and Kinra, V.K., “An Experimental Technique for Determining a Measure of Structural Damping,” ASTM J. Test. and Eval., 77–85 (Jan. 1988).

Wren, G.G. andKinra, V.K., “An Experimental Study of the Complex Dynamic Modulus, Dynamic Elastic Modulus Measurements in Materials,”ASTM STP 1045, ed. Alan Wolfenden Amer. Soc. for Test. and Mat., Philadelphia (1989).

Timmerman, N.S. and Doherty, J., “Loss Factors in Metal Matrix Composites,” Army Mat. and Mech. Res. Center, Final Rep., AMMRC TR 84-22 (June 1984).

Timmerman, N.S., “Damping Characteristics of Metal Matrix Composites,” Army Mat. and Mech. Res. Center Rep., AMMRC-TR-82-19 (April 1982).

Crawley, E.F. and Sheen, R.L., “Experimental Measurement of Material Damping in Space Structures,” Proc. Vibration Damping Workshop, AFWAL-TR-84-3064, F-2 (1982).

Crawley, E.F. andvan Schoor, M.C., “Material Damping in Aluminum and Metal Matrix Composites,”J. Comp. Mat.,21,553–568 (June 1987).

Ramnath, V. and Humphreys, E.A., “Analysis of Material Damping in Metal Matrix Composites,” Material Science Corporation, Technical Final Report, MSC TFR 1709/7303 (Nov. 1986).

Misra, M.S. and LaGreca, P.D., “Damping Behavior of Metal Matrix Composites,” Proc. Vibration Damping Workshop, AFWAL-TR-84-3064, U-1 (Nov. 1984).

Steckel, G.L. andNelson, B.A., “Mechanical Damping Behavior of Graphite-Magnesium,”Aerospace Corporation Rep. No. TOR-0086(6726-01)-1, The Aerospace Corporation, El Segundo, CA (Oct. 1985).

Stroganova, V.F., “Magnesium Based Composites,” Proc. First Japan-ISSR Symp. on Comp. Mat., 238–250.

Steckel, G., “Material Damping Behavior of Gr/Mg Composites,” Aerospace Corporation, ONR Rep. No. TOR-0084-A-5726-01(-1) El Segundo, CA (Oct. 1985).

Kreider, K.G. andPrewo, K., “Boron Reinforced Aluminum,”Comp. Mat.,4,Academic Press.,422–428 (1974).

DiCarlo, J.A. and Maisel, J.E., “Measurement of Time-Temperature Dependent Dynamic Mechanical Properties of Boron-Aluminum Composites,” Composite Materials: Testing and Design (Fifth Conference), ASTM STP 674, ed. S.W. Tsai, Amer. Soc. for Test. and Mat., 201–227 (1979).

DiCarlo, J.A., “Fibers for Structurally Reliable Metal and Ceramic Composites,” J. Metals, 44–49 (June 1985).

Datta, S.K. andLedbetter, H.M., “Anisotropic Elastic Constants of a Fiber-Reinforced Boron-Aluminum Composite,”Mechanics of Non-Destructive Testing ed. W.W. Stinchcomb, Plenum Press, New York, 215–230 (1979).

Kasai, Y., Saito, M. andAsaka, C., “Application of New Substrateless Continuous SiC Filament to Metal Matrix Composite Materials,”Japanese Composite Materials Institute (JCMI),5 (2),56–61 (1979).

Abe, Y., Horikiri, S., Fujimura, K. and Ichiki, E., “High Performance Alumina Fiber and Alumina/Aluminum Composites,” Proc. 4th Int. Conf. on Comp. Mat. (ICCM-IV), (1979).

DiCarlo, J.A. and Misel, J.E., “High Temperature Dynamic Modulus and Damping of Aluminum and Titanium Matrix Composites,” Advanced Fibers and Composites for Elevated Temperatures, ed. I. Ahmad and B.R. Noton, Conf. Proc. of The Metallurgical Society of AIME, 108th AIME Annual Meeting, New Orleans (Feb. 20–21, 1979).

Smith, P.R. and Froes, F.H., “Developments of Titanium Metal Matrix Composites,” J. Metals, 19–26 (March 1984).

Bhagat, R.B., Amateau, M.F. and Smith, E.C., “Damping Behavior of Squeeze Cast Planar Random Carbon Fiber Reinforced 6061 Aluminum Matrix Composite,” to appear in J. Comp. Tech. and Res.

DiCarlo, J.A., unpublished work received personally from Dr. J.A. DiCarlo, NASA-Lewis Research Center, Cleveland, OH (Sept. 1989).

Zener, C., Elasticity and Anelasticity of Metals.,Univ. of Chicago Press, Chicago (1948).

Lazan, B.J., Damping of Materials and Members in Structural Mechanics, Pergamon Press, Oxford (1968).

Granick, N. andStern, J.E., “Material Damping of Aluminum by Resonant Dwell Technique”,NASA Tech. Note, TN D-2893, Goddard Space Flight Center, Breenbelt, MD (1964).

James, D.W., “High Damping Metals for Engineering Applications,”Materials Science and Engineering,4 1 (1969).

Weissman, G.F. andBabington, W., “A High Damping Magnesium Alloy for Missile Applications,”ASTM Proc.,58,869–892 (1958).

Schwaneke, A.E. andNash, R.W., “Effect of Preferred Orientation on the Damping Capacity of Magnesium Alloys,”Metallurgical Transactions 2,3453 (1971).

Sugimoto, K., Matsui, T., Okamoto, T. andKishitake, K., “Effect of Crystal Orientation on Amplitude Dependent Damping, in Magnesium,”Trans. Japan Inst. of Metals,16,647–655 (1975).

Sugimoto, K., Niiya, K., Okamoto, T. andKishitake, K., “A Study of Damping Capacity in Magnesium Alloys,”Trans. Japan Inst. of Metals,18,277–288 (1977).

Korb, L.J., “Space Vehicles,”Composite Materials,3 —Engineering Applications of Composites,ed. Bryan R. Norton,Academic Press,New York (1974).

Engineered Materials Handbook—Volume 1: Composites, ASM International, Metals Park, OH (1987).

Rosen, B.W., “Thermomechanical Properties of Fibrous Composites,”Proc. Roy. Soc. London-Series A,319,79–94 (1970).

Rosen, B.W. andHashin, Z., “Effective Themal Expansion Coefficients and Specific Heats of Composite Materials,”International J. Eng. Sci.,8,157–173 (1970).

Hashin, Z., “Analysis of Properties of Fiber Composites with Anisotropic Constituents,”J. Appl. Mech.,46,543–550 (Sept.1979).

Hashin, Z. andRosen, B.W., “The Elastic Moduli of Fiber Reinforced Materials,”J. Appl. Mech.,31,223–232 (June1964)Errata, 219 (March 1965).

Hashin, Z., “Complex Moduli of Viscoelastic Composites—II. Fiber Reinforced Materials,”Int. J. Solids and Struct.,6,797–807 (1970).

Ni, R.G. andAdams, R.D., “The Damping and Dynamic Moduli of Symmetric Laminated Composite Beams—Theoretical and Experimental Results,”J. Comp. Mat.,18,104–121 (March1984).

Kinra, V.K., Wren, G.G., Rawal, S.P. andMisra, M.S., “On the Influence of Ply-Angle on Damping and Modulus of Elasticity of a Metal-Matrix Composite,”Metallurgical Transactions,22A,641–651 (March1991).

Jones, R.M. Mechanics of Composite Materials, McGraw-Hill Book Co., New York (1975).

Snowdon, J.C., Vibration and Shock in Damped Mechanical Systems, J. Wiley & Sons, New York (1968).

Schapery, R.A. “Stress Analysis of Viscoelastic Composite Materials,”Mech. of Comp. Mat.,1,228–267 (1967).

Schapery, R.A., “Viscoelastic Behavior and Analysis of Composite Materials,”Mech. of Comp. Mat.,2,ed. G.P. Sendeckyj,Academic Press,New York,85–168 (1974).

Metals Handbook, 9th Ed.,2 (1979).

DWA Composite Specialties, 21119 Superior Street, Chatsworth, CA 91311, Tel. (818) 998–1504, FAX (818) 709–1846.

Chamis, C.C. and Sinclair, J.H., “10° Off-Axis Tensile Test for Interlaminar Shear Characterization of Fiber Composites,” NASA Tech. Note, TN D-8215, Lewis Research Center, Cleveland, OH (April 1976).

Personal communication with Dr.S.P. Rawal, Martin Marietta, Aerospace Corporation, Denver Division, Littleton, CO 80127 (Nov. 1988).

Wren, G.G. and Kinra, V.K., “Damping in Metal-Matrix Composites,” Dept. of Aerospace Engineering Rep., Texas A&M Univ., College Station, TX 77843.

Thornel Product Information, Amoco Performance Products, Inc., 39 Ridgebury Road, Danbury, CT 06817.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Wren, G.G., Kinra, V.K. Axial damping in metal-matrix composites. II: A theoretical model and its experimental verification. Experimental Mechanics 32, 172–178 (1992). https://doi.org/10.1007/BF02324729

Received:

Revised:

Issue Date:

DOI: https://doi.org/10.1007/BF02324729